3D printing redefined: Stratasys aims to innovate its way out of malaise with J750

Stratasys has launched a 3D printer dubbed the J750 that allows enterprises to mix and match colors and materials to create prototypes that come close to production products faster. The launch may leave rivals scrambling.

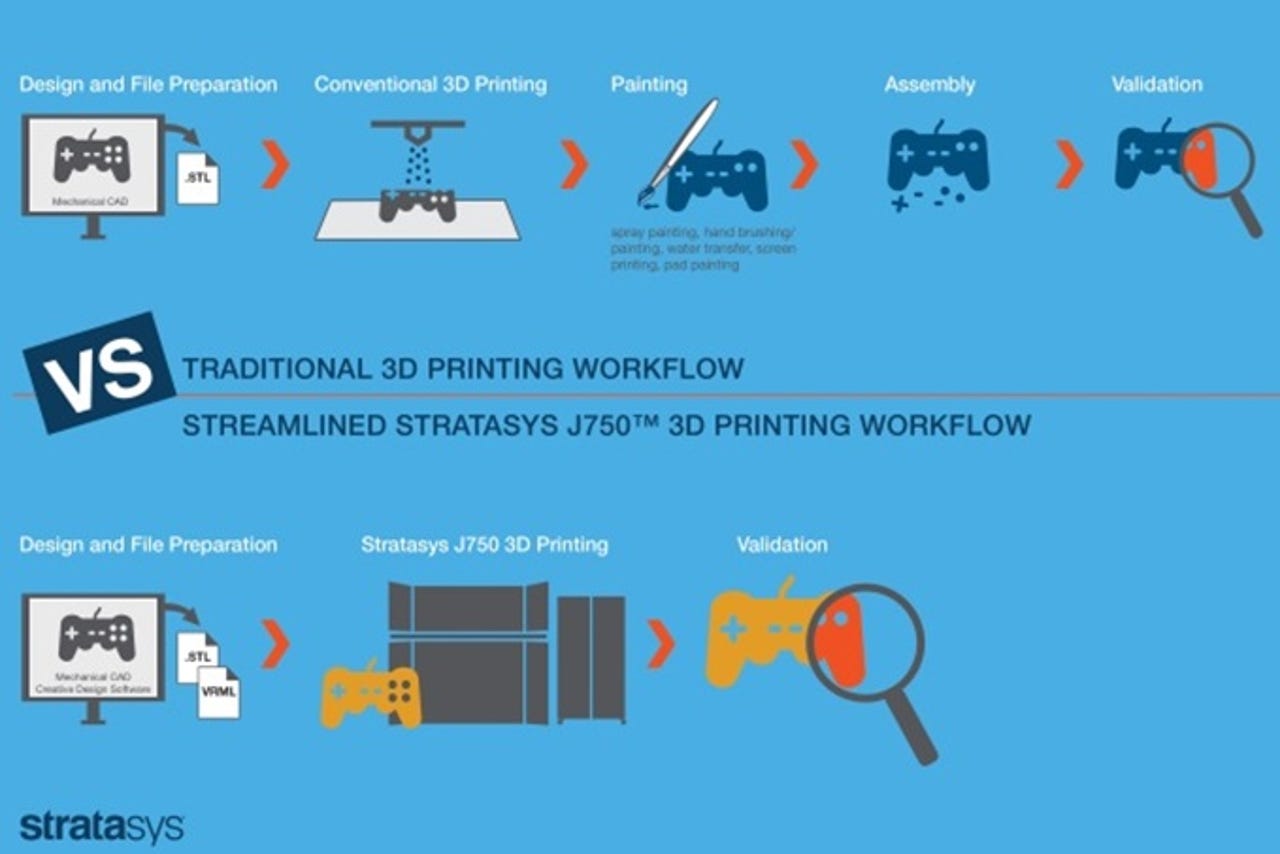

More importantly, Stratasys has cut two steps from the 3D printing workflow in additive manufacturing prototypes. Add it up and Stratasys' J750 has the mojo to spur a buying cycle for manufacturers and companies looking to create parts and prototypes faster.

In a nutshell, Stratasys has eliminated steps such as painting and assembly from traditional 3D printing workflows.

The big question: Is Stratasys' innovation enough to rekindle growth in the 3D printing market? Time will tell, but we'll find out soon enough: The J750 is available immediately although delivery times vary by region.

For Stratasys, the J750 is critical to boost sales and offset a slowdown in demand among manufacturers. In addition, HP is expected to enter the 3D printer market later this year and its guns are aimed at Stratasys. HP's upcoming entry into the market along with a volatile economic picture have curbed demand.

TechRepublic: Stratasys re-energizes 3D printing with push-button J750 that prints 360,000 colors

And while the 3D printing market has appeared to have bottomed. Stratasys has said that demand is hard to predict and projected 2016 revenue growth of 1 percent to 5 percent. 3D Systems said it was seeing improvement in its key verticals, but most analysts aren't expecting a return to the heady growth just a few years ago.

Also: How GE is using 3D printing to unleash the biggest revolution in large-scale manufacturing in over a century | 3D printing hands on: How to design your first 3D project without tears | 3D printing pirates: When eBay thieves profit from your work | 3D printing nears inflection point; Mattel ThingMaker may make it mainstream

That backdrop is what makes the J750 launch so interesting. Stratasys is clearly aiming to lock down its core enterprise market, make HP irrelevant before it even enters the market and innovate its way to growth. We sent TechRepublic's Jason Hiner to check out the J750 in action as well as early customers such as OtterBox. His take is that Stratasys is onto something potentially big and is closer to "the way we all thought 3D printing should work" because "it's a lot more push-button."

Perhaps a push button 3D printing system will convince more enterprises to take the plunge. TechPro Research found a lot of corporate fence sitters when it comes to 3D printing.

If companies can prototype faster and ultimately evolve to manufacture from these systems the returns to them will be worthwhile.

According to Stratasys, its ability to eliminate post processing from the 3D printing equation will resonate with designers, engineers, manufactures and service bureaus, which are the target market for HP.

OtterBox is already touting the J750 as a game changer. The J750 is the lead dog in Stratasys' Objet Connex multi-color, multi-material 3D printer line and can choose from 360,000 color shades. The system runs on Stratasys' PolyJet Studio software that plugs into design tools.

Stratasys launches J750 3D printer: Here's a look at what it can do

As for the total cost of ownership, Stratasys is betting that the J750 will cut time, money and resources needed to create multiple prototypes close to real products. The upshot is that Stratasys can move a product from an engineer's head to a physical prototype in hours.

Should Stratasys' J750 live up to its advance billing it could magnify the effect 3D printing has already had on the supply chain. At the very least, Stratasys has given rivals technology to chase.