Circuit-printing startup reaches 30-day Kickstarter fundraising goal in 5 hours

A group of University of Queensland engineering graduates has blown past expectations by hitting their Kickstarter fundraising goal of $30,000 – designed to help them commercialise an innovative printer that can print working electronic circuits on a piece of paper – in just five hours.

Mechanical engineer John Scott, electrical engineer Ariel Briner and software engineer Isabella Stephens hit upon the idea for their 3D circuit board printer while still students.

Their goal was to speed the process of manufacturing the printed circuit board (PCB) boards used in any type of electrical product.

Such boards are normally manufactured using a complex etching process that uses acid to remove the unnecessary parts of a copper sheet, leaving only the traces that form part of the design. Manufacturing the boards has typically required sending designs – created using software such as CadSoft's EAGLE – to overseas production houses and waiting for weeks until the manufactured board arrives.

Briner had several ideas about improving this process during university, but “it didn't really work out because I was trying some crazy solution that was really hard,” he recalls. “I wasn't thinking about what would actually make for a good project.”

The idea was later revived during a conversation with Scott, and after the team was picked up by a U of Q-owned startup incubator called iLab the idea began to gain momentum.

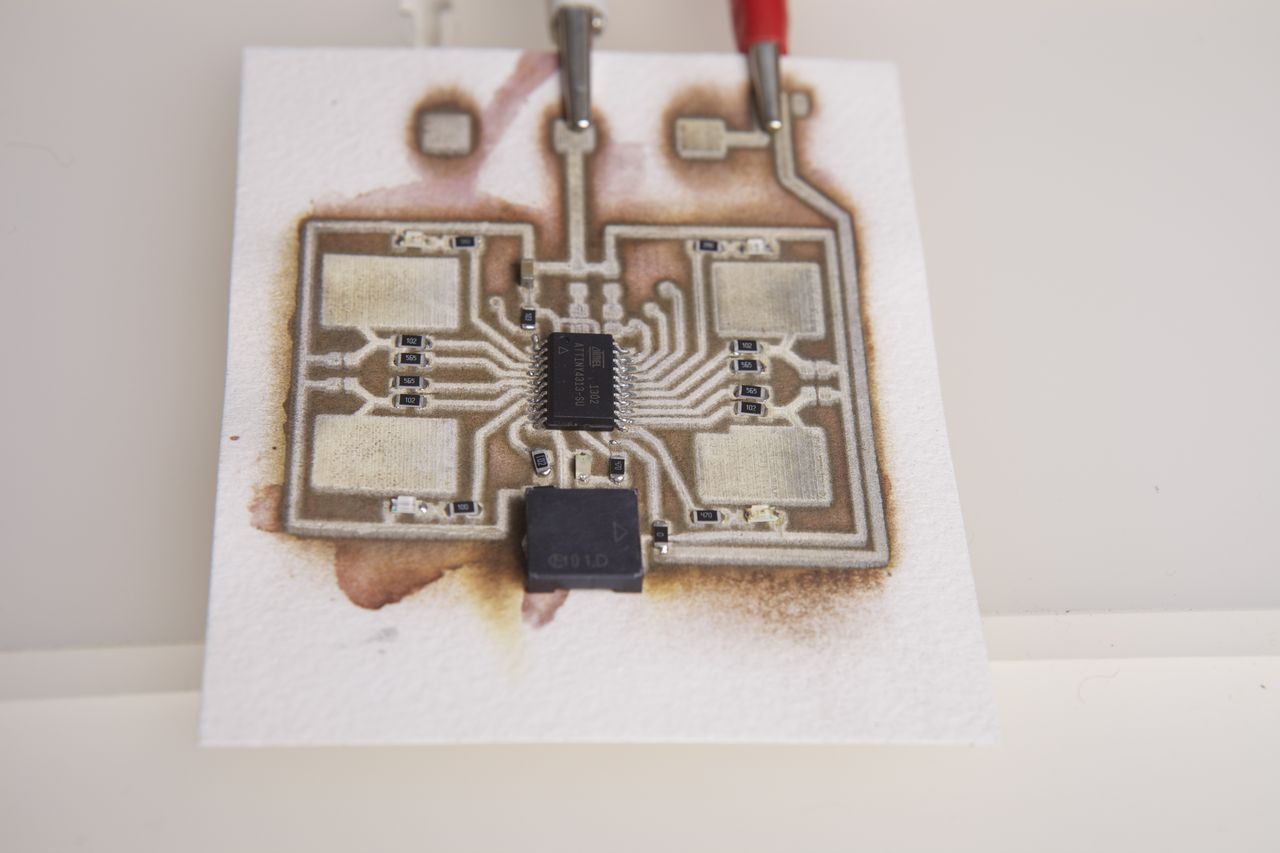

The result – the EX1 printer, which works like an inkjet printer but lays down elemental silver onto a range of substrates including plastic, wood, ceramic, silicone, fabric and paper – took nine months to develop. Aiming to fund commercialisation of the product, the team went to Kickstarter in the hopes that it could raise $30,000 within 30 days.

The project – one of the first Australian ventures to be posted on Kickstarter (see the project here) – ultimately raised the $30,000 within five hours and, three days into its run, had attracted $87,756 from 184 different backers.

That response not only blew away the team, but highlighted the interest in their technology and the potential market for it.

“Just by talking to our friends, we knew there would be a certain, select few people that would definitely be interested in it,” says Scott.

“But we didn't really know if it would be quite widely picked up. We're really happy that everyone gets what we're doing; even if they're not a technical person, they understand that this is something really big.”

The company they created to handle the product, Cartesian Co., has costed its manufacture in great detail and worked carefully to ensure a sustainable business model.

“You've got to be careful because many Kickstarter campaigns are fast and loose with how hard it's going to be to manufacture things,” Briner warns. “We have done a lot to make sure it's delivered on time and on budget. But because of the way we designed it, we didn't really need that much to get into production.”

Backers will get first dibs on the printers, which Briner says will ship by mid 2014 for an rrp of $1199 and are built using off-the-shelf components.

The team will keep manufacturing inhouse for now, ensuring a high degree of control over the process: “If we outsource it we can't make sure that every printer that goes out is perfect,” Briner says.

The benefits for frequent PCB makers are significant: one New Zealand manufacturer, that Scott often uses, typically turns around designs within ten days and charges around $50 for a small PCB, while Chinese manufacturers can deliver the same design for around $20 but take up to a month for delivery.

The EX1 printer, by contrast, can produce a working PCB prototype within an hour, at a cost of just a few dollars in consumables. The metallic traces can be made as thick as the designer wants to make them, and the ability to print on a range of materials – paper, surprisingly, has turned out to be the best option – paves the way for the easy manufacture of everything from LED-illuminated jewellery to video game controllers.

Because designs can be created in any desktop graphics software – ranging from Windows Paint to Adobe Illustrator – Briner even envisions the product being used by artists to build illumination, lights and interactivity into their works of art (the printer also supports standard inkjet cartridges).

“The whole process is a lot faster and easier,” Briner says. “When you make boards with the acid etching process, you are hands on – whereas with our solution you just push a button. It's the equivalent to cooking in a microwave compared with doing it over a fire.”