Five-fingered robot hand has a mind of its own

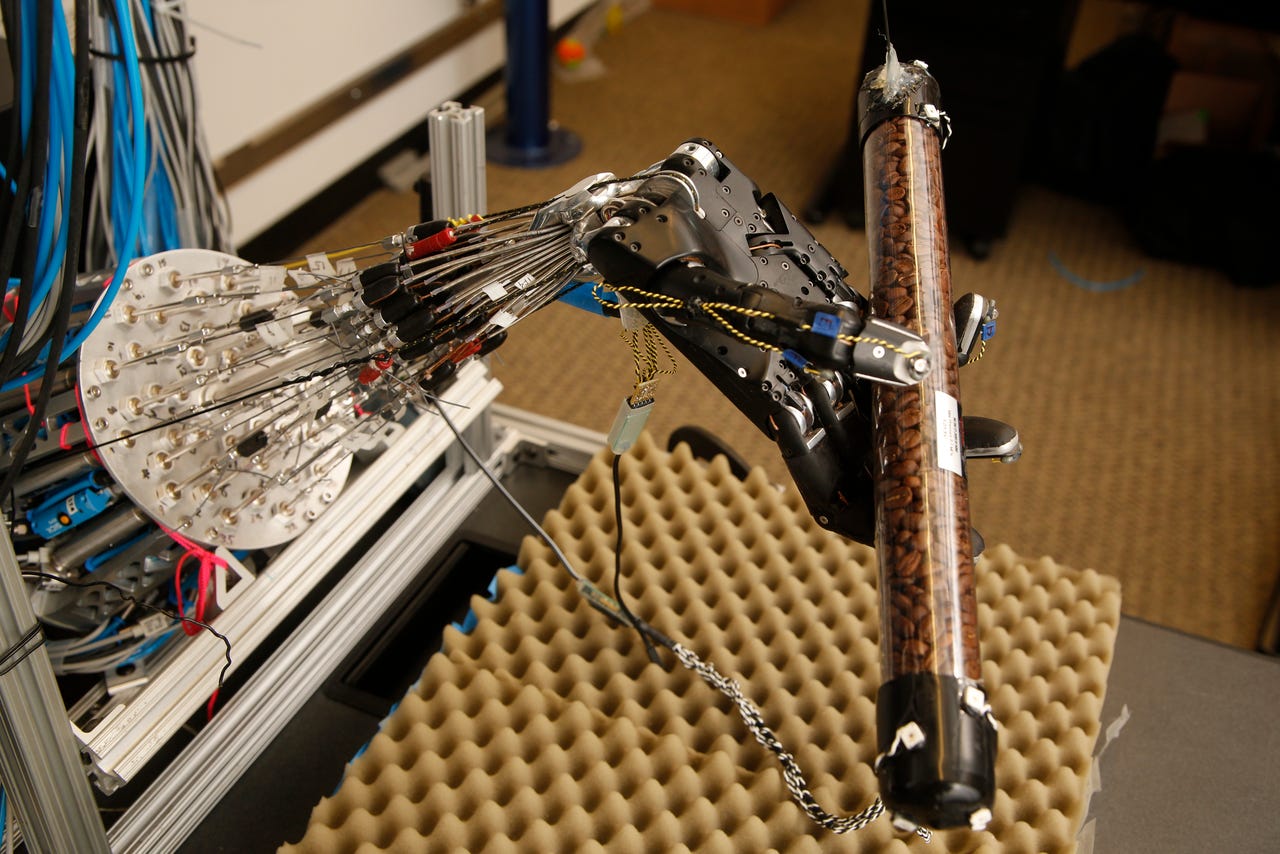

The University of Washington's dexterous robotic hand grasping a cylinder.

Writers rejoice: Of all the manipulation tasks robots can now perform, the act of picking up a pencil and holding it with a standard writing grip has been beyond the abilities of even the most dextrous bots.

Until now (sorry, scribe brethren.)

A University of Washington team of computer scientists and engineers has built a bot hand that can not only perform dexterous manipulation but is also able to learn from its own experience without human direction or intervention. It's part of a trend in robotics that's seen artificial intelligence applied to all manner of tasks, from computer vision and language learning to the mysteries of the bipedal gait.

"Hand manipulation is one of the hardest problems that roboticists have to solve," according Vikash Kumar, a UW doctoral student in computer science and engineering. "A lot of robots today have pretty capable arms, but the hand is as simple as a suction cup or maybe a claw or a gripper."

The UW team took a different approach, creating what may be the most complex and dexterous mechanical hand in the world. But the secret sauce isn't in the hardware. The researchers developed a simulation model that allows a computer to analyze movements in real time. With each of the hand's attempts at manipulating an object, such as a large tube or something skinnier, like a pencil, the computer learns the basic physics involved in the scenario and becomes more adept at figuring out which actions will yield the desired result.

In the video, you can see the simulated hand tossing an object in the air to get a better grip, an action that was learned autonomously through trial and error.

Robotics

"Usually people look at a motion and try to determine what exactly needs to happen--the pinky needs to move that way, so we'll put some rules in and try it and if something doesn't work, oh the middle finger moved too much and the pen tilted, so we'll try another rule," said senior author and lab director Emo Todorov, UW associate professor of computer science and engineering and of applied mathematics.

"It's almost like making an animated film--it looks real but there was an army of animators tweaking it," Todorov said. "What we are using is a universal approach that enables the robot to learn from its own movements and requires no tweaking from us."

The UW hand cost about $300,000 to build, making it too expensive for most applications. But the algorithms developed to teach the hand can be broadly adapted to industry, where a learning robot could be deployed on a manufacturing floor to perform assembly requiring fine motor skills. Today most industrial robots require careful programming and dialing in during an intensive setup phase, which usually requires plants to go offline temporarily. Self-learning robots will soon reduce costs and downtime, increasing productivity and creating what has been called a new industrial revolution.

So far, the UW researchers have demonstrated that their hand can continue to improve at a discrete task that involves manipulating the same object in roughly the same way. The next phase will focus on demonstrating global learning, in which the hand will learn how to manipulate an object it hasn't encountered before.