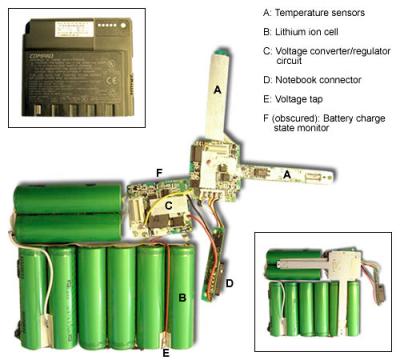

Inside a notebook battery pack

Lithium ion batteries aren't so much popular in modern mobile IT as essential. The unique combination of low mass, small size and high power storage capabilities makes the technology as much part of notebook and mobile phone design as liquid crystal displays and high-impact plastic.

Those same attributes make lithium ion dangerous. The amount of energy needed to keep a notebook as warm as toast for four hours will melt steel if it's expressed in a few seconds -- and a damaged Li-ion battery can dump power that fast. The damage can be external, as when an impact deforms the case, or it can be due to manufacturing defects. Many dangerous situations are avoided by the internal geometry of the cells and smart support electronics -- there's far more to modern battery design than you may think.

The most impressive part of lithium ion batteries isn't that they can go catastrophically wrong, but that they only do so rarely -- one or two times per million units per year. Here's what's inside the case, keeping you safe and your notebook running.

Temperature sensors

When assembled, these two arms run alongside two of the cells in the battery stack (see inset, above), monitoring the overall pack temperature. If this reaches a high level for whatever reason, the electronics isolates the batteries from charging or discharging. The notebook may also have temperature sensors in the battery compartment, feeding its own safety systems.

Lithium ion cell

One of eight in the example above, this contains about six watt-hours of energy. That translates to two kilowatts over ten seconds, a rate of discharge that's theoretically possible under some fault conditions. Excessive heating in one cell can cause the failure of the next, and so on, an avalanche effect that leads to the energetic destruction of the entire pack.

Voltage converter/regulator circuit

This maintains safe levels of voltage and current during charging and discharging. Although it's designed to spot dangerous conditions and prevent cell damage by shutting down the battery pack, component faults here can actually increase the risk of catastrophic failure.

Notebook connector

This is shrouded and designed to minimise the risk of short circuits when the battery pack is separate from the main equipment. Even if the plastic shroud is damaged, the circuitry inside the pack should detect short circuit conditions and protect the cells from rapid discharge.

Voltage tap

Most consumer equipment treats a stack of cells as a single battery, but this can be dangerous in lithium ion. As the cells age, some will lose capacity faster than others -- and if one cell becomes flat before the others, it can actually start to charge in reverse, which is a highly dangerous condition. The internal circuitry of the battery pack thus has to monitor cells separately and shut down the whole pack if one cell is too far out of balance.

Battery charge state monitor

Many lithium ion packs have a built-in meter consisting of a row of LEDs and a button. To accurately report the state of charge, the pack electronics has to keep a record of the current in and out of the cell, as well as a model of its behaviour. This can become more inaccurate over time; more modern cells will recalibrate themselves.

More information about battery control technology can be found at the industry forum for the Smart Battery System specification.