Mars Rover laser tech to boost Aussie mining

The Australian mining industry is looking to harness laser technology used by NASA to analyse minerals on Mars.

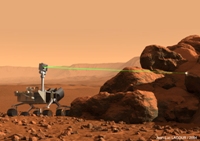

An artist's impression of the ChemCam laser in action

Credit: Jean-Luc Lacour, CSR/LANL

Australia's mining industry is poised to make use of laser technology developed for the Mars Rover, which, with a little tweaking, could significantly improve the efficiency of mineral exploration on earth.

Dr Brian McInnes, stream Leader of exploration and mining at research organisation CSIRO, recently visited NASA and affiliated US institutions such as the Los Alamos National Laboratory to investigate technology transfer projects where space applications can be adapted for use in Australia's mining industry.

One of the more exciting technologies under consideration is a laser spectroscopy instrument called ChemCam, developed for the 2009 NASA Mars Science Laboratory mission, which can remotely determine the geochemistry of rocks and minerals.

"There is currently no method available to the [mining] industry for analysing the chemistry of rocks remotely," said McInnes.

Such technology, he said, could provide a safe way of collecting data at isolated or hazardous sites.

"The key thing is getting the data in real time", he told ZDNet.com.au, an improvement on the industry's current analysis process, which involves sending a sample away and waiting weeks or months for the results.

ChemCam's laser beam strikes a rock within the Mars sample chamber

Credit: Los Alamos National Laboratory

It could also help ease the skills shortage in the resources sector, he said, because industry can use the instrument to automatically collect information, as opposed to sending a team.

ChemCam works by firing a high-powered laser at a sample of rock, heating it to a temperature high enough to produce plasma — a form of superheated gas that emits light. The emitted light from the rock can be picked up via a mini-telescope and can then be analysed to determine the exact composition of the rock via spectroscopy — a chemical technique used to examine elements based on the absorbency and emission of different wavelengths of light.

The problem with previous instruments used on rovers, according to Roger Wiens, ChemCam project leader Los Alamos National Laboratory, is that rocks are often covered with dust and weathering layer. If the instrument just takes an image it will only be looking at the outer surface. "What is really inside the rock is what we're interested in," he said in a YouTube video (see below).

ChemCam Mast Unit being prepared for laser firing

Credit: Los Alamos National Laboratory

The first laser shots remove the dust and the weathering layers to access the rock underneath.

McInnes's team has been in talks with the mining industry to see if there is potential for a commercial application of the technology. Both Rio Tinto and BHP Billiton, McInnes said, have "very positive things" to say about the technology and are putting the idea in front of management.

The key consideration, McInnes said, is to determine how the technology might be adapted for use by mining companies. "[ChemCam] was built for pure scientific research," he said, adding that the needs of the company may be different if it is operating a nickel mine to if it is operating an iron ore mine. "It's not a one solution fits all," he said. "We may need to tweak the system."

If industry decides there is scope for a commercial product, it would take two to three years to get a working prototype, McInnes said.

Here is a YouTube video describing how ChemCam works.