Molybdenite microchip promises flexible electronics

Swiss scientists say they have a new candidate for making flexible electronic devices, after they successfully manufactured the first molybdenite microchip.

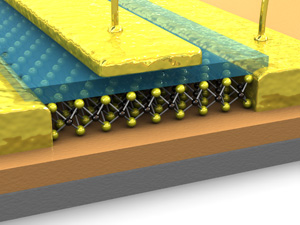

Swiss researchers have made a prototype microchip using a substance called molybdenite, which could prove to be a rival to both silicon and graphene. Image credit: Lanes

The integrated circuit was made at the Laboratory of Nanoscale Electronics and Structures (Lanes), of the École Polytechnique Fédérale de Lausanne (EPFL). On Monday, the researchers said it showed how molybdenite microchips could be made smaller than silicon chips, use less electricity than silicon, and be more flexible than silicon, the mainstay of today's computers.

The flexibility of molybdenite could also make it suitable for creating rollable computers or devices that can be attached to a person's skin, the researchers said.

"We have built an initial prototype, putting from two to six serial transistors in place, and shown that basic binary logic operations were possible, which proves that we can make a larger chip," Lanes director Andras Kis said in a statement.

Kis had two articles on the molybdenite research published in the ACS Nano scientific journal last month.

Potential rival to silicon

The EPFL first began talking up molybdenite, or molybdenum disulphide (MoS2), earlier this year, when it pointed out its potential in computing. The substance has good semiconducting properties, which positions it as a rival to silicon, albeit one that allows for greater miniaturisation.

"The main advantage of MoS2 is that it allows us to reduce the size of transistors, and thus to further miniaturise them," Kis said. Layers of silicon cannot be less than 2nm thick, otherwise they oxidise and stop working. Molybdenite can work at a thickness of three atoms with a diameter of 0.2nm, so chips made using the substance can be at least three times smaller than those made with silicon.

Molybdenite is also being compared to graphene, the graphite-derived material that many see as silicon's successor. Like graphene, molybdenite comes in flexible, stretchable two-dimensional layers that can be peeled off the bulk material using sticky tape.

However, MoS2 has some key advantages over graphene. One of the big problems with graphene is the fact that it does not have a band gap, which means transistors made using graphene cannot be fully switched off. Like silicon, molybdenite does have a band gap.

Crucially, molybdenite can, like silicon, amplify electronic signals

at ambient temperatures — graphene normally needs to be cooled down to

cryogenic

temperatures in order to work in this way, although recent research at Purdue University has demonstrated working graphene logic circuits at normal room temperature.

According to Kis, molybdenite has similar amplification abilities to silicon, making it viable for complex chips. This compares well to graphene, which has about a quarter of that performance.

Get the latest technology news and analysis, blogs and reviewsdelivered directly to your inbox with ="http:>ZDNet UK'snewsletters.