Robotics and Industry 4.0: Reshaping the way things are made

It seems like there's more talk these days about Industry 4.0 -- or the fourth industrial revolution -- and robotics, along with other technologies that will play a role in this megatrend.

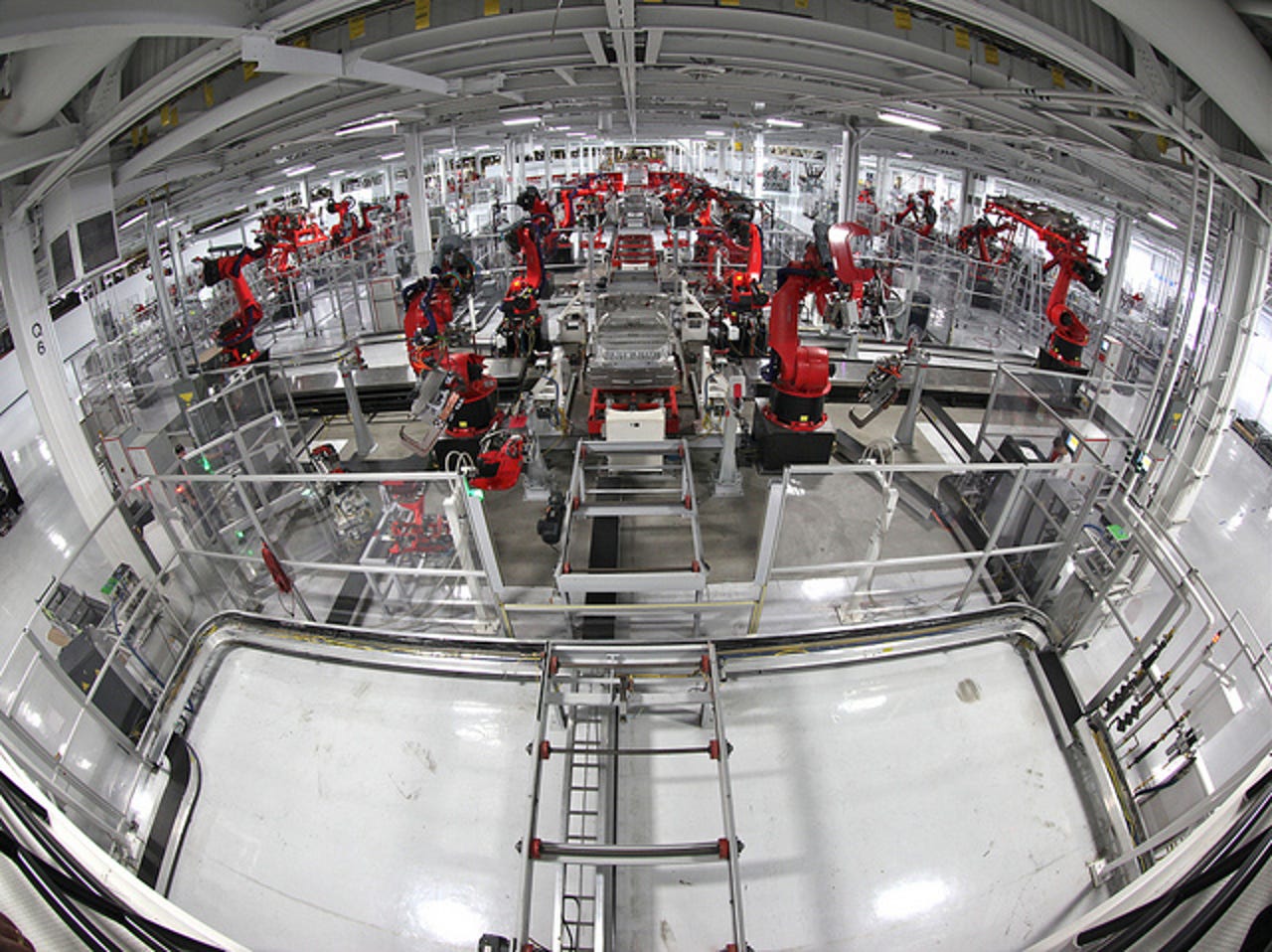

Industry 4.0 is a confluence of trends and technologies that could reshape the way things are made. (Image: Tesla)

Industry 4.0 involves the heavy use of automation and data exchange in manufacturing environments, encompassing areas such as cyber-physical systems, the Internet of Things (IoT) and cloud computing, among others. With Industry 4.0, manufacturers will be able to operate "smarter" factories, in which they can more easily tailor products for specific customers.

This new phase in manufacturing is so named because it follows the previous manufacturing phases of water/steam power, electric power, and computing power. A lot of the technologies organizations are deploying today, such as big data/analytics, cloud services, and augmented reality, will also have a part in Industry 4.0.

Management consulting firm McKinsey and Company noted that Industry 4.0 "is more than just a flashy catchphrase. A confluence of trends and technologies promises to reshape the way things are made."

The trend is gathering force, the firm said, and advised executives to carefully monitor the coming changes and develop strategies to take advantage of the new opportunities. It sees the trend being driven by four disruptions: the dramatic increase in data volumes, computational power, and connectivity; the emergence of analytics and business-intelligence capabilities; new forms of human-machine interaction; and improvements in transferring digital instructions to the physical world, such as advanced robotics and 3D printing.

While some of these technologies aren't yet ready for application at scale, McKinsey said, many are now at a point where their greater reliability and lower cost are beginning to make sense for industrial applications.

Robotics is part of the Industry 4.0 picture. The market for smart machines in the Americas, including autonomous robots, expert systems, and digital assistants, is growing, in large part because of the rise of Industry 4.9, according to a recent report from Technavio Research.

The firm's analysts predict that the market will increase at a compound annual growth rate (CAGR) of 15 percent between 2016 and 2020. The smart machines fix and prevent processing errors that can happen because of the wear and tear of mechanical components. They are capable of storing information about a series of processes and machine conditions because they're equipped with sensors, the report said.

The growing concept of Industry 4.0 in the automotive, electrical, and electronics industries is key for the growth of the smart machines market in the Americas, Technavio said.

The need to monitor and evaluate real-time data and the process of streamlining the manufacturing set-up process has increased investments in smart machines with artificial intelligence technology, said Bharath Kanniappan, lead analyst of industrial automation at Technavio.

Manufacturers that want to get in on the Industry 4.0 trend need to be looking at these technologies now and considering the shifts they will need to make. As McKinsey noted, the traditional manufacturing business model is changing and new models are emerging. To get the most out of Industry 4.0 technologies, companies will need to get ready for a digital transformation.