This robot miner will soon be exploiting resources humans can't reach

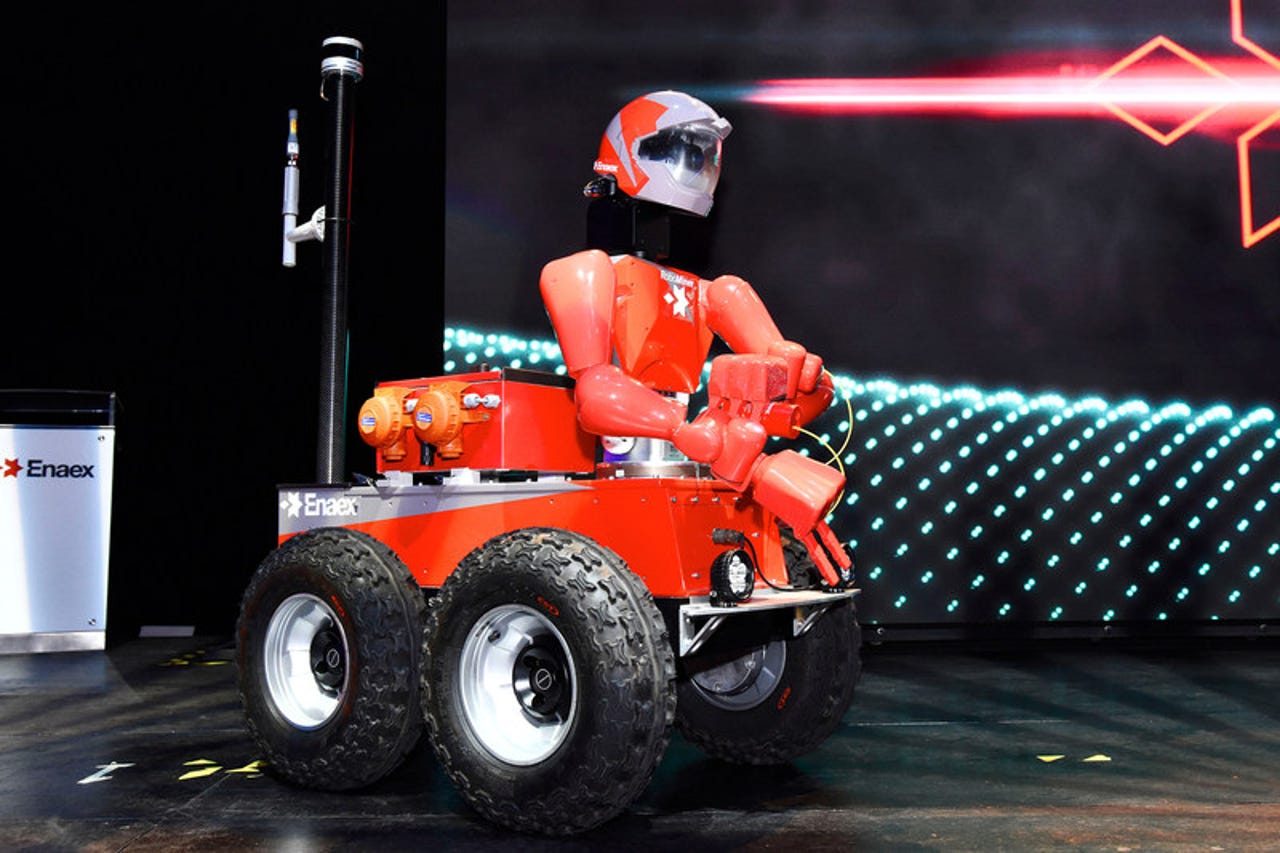

Enaex, which supplies blasting services for mine operators, recently teamed up with Silicon Valley-based R&D organization SRI International to see if they could create a robot miner. They're calling their automated solution, somewhat uncreatively, RoboMiner.

Robotics

Mining is an inherently dangerous profession, and the industry has long sought to mitigate the danger through technology.

In the early twentieth century, mine operators started using sentinel species -- canaries, most famously -- to detect the presence of poisonous gases like carbon monoxide. That technique, pioneered by British doctor John Scott Haldane, has since been replaced by electronic detectors, which warn miners to evacuate when the air becomes unbreathable.

But dangers persist. Cave-ins, explosions, and heavy-equipment all contribute to the risks, and while statistics are sketchy, globally the mining industry may lose up to 12,000 workers per year due to fatalities.

Robots could provide a much-needed solution.

SRI's device, which is more accurately described as a tele-operated humanoid, can be dispatched to dangerous mine environments and controlled remotely. That enables operators to reach areas that present a high level of risk for human life.

It may also allow mining companies to go after resources whose exploitation is impossible right now, according to an SRI spokesman.

The mining industry already uses autonomous equipment. In Australia, mining company Rio Tinto operates 73 self-driving trucks. The trucks are the size of a two-story house and operate with no humans onboard.

But many mining tasks require dexterity and the ability to navigate unstructured environments -- in other words, require humans. SRI's solution may change that. It may also make the mining industry the proverbial canary in the coal mine for the expansion of automation in related industries, such as construction.

Coverage of the debut has been sparse, but I managed to speak with an SRI representative to fill in some gaps.

RoboMiner consists of a humanoid torso, head, and arms mounted on a 4-wheeled mobile platform. It is capable of moving at human speeds, has stereo vision, and can handle payloads just as miners in typical Enaex operations can.

Sarcos Robotics' Guardian GT

The system reminds me a bit of Sarcos Robotics' Guardian GT robot, another tele-operated unit, which I recently got a chance to try and will be covering in an upcoming post. The GT is built to operate in dangerous settings like nuclear power plants, but ultimately its creators envision it becoming commonplace on construction sites.

More proof that the next generation of blue collar job may involve driving a robot.

RoboMiner will initially operate in open pit mines, but the plan is to eventually use it underground. That's important because underground mines expose workers to a wide range of potential environmental risks, including high and low temperatures and wet and dusty conditions.