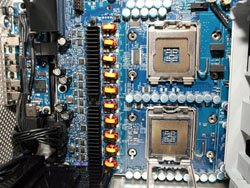

Inside Apple's blue logic boards

G10-FR4 (FR4) is a fire rated electrical-grade, dielectric fiberglass laminate epoxy resin system combined with a glass fabric substrate. The abbreviation "FR4" means: F (for flame) and R (for retardancies) and the 4 is a # 4 epoxy. FR4 grades offer excellent chemical resistance, flame ratings (UL94-VO) and electrical properties under dry and humid conditions.

FR4 also features high flexural, impact, superior mechanical strength and bond strength at temperatures up to 130°C. G10-FR4 is suitable for structural, electronic, pc boards and electrical applications.

According to a colleague who has worked in the semiconductor industry for years blue boards used to be less reliable and more prone to wiskering (copper migrating between plated through holes and shorting connections) and were not as temperature stable as their green G10-FR4 counterparts.

Some have speculated that Apple may have moved to the new blue boards to be more "green" but this is unconfirmed. Others have mentioned that the switch to blue boards is cosmetic only and that the blue material has the same characteristics as green.

Most of Apple's products now ship with blue logic boards:

- MacBook (pictures)

- MacBook Pro 15" (pictures)

- iMac Core Duo (pictures)

- Mac mini Core Duo (pictures)

- Mac Pro Blue (pictures)

- Xserve (pictures)

It looks as if Apple is the next Big Blue if our logic boards are any indication. Apple declined to comment on this story.

I have posted a gallery of images of the MacBook Pro Core Duo and Core 2 Duo logic boards.

(Thanks to Kenn Marks for his research on the subject.)