Trash to cash, any investor's dream

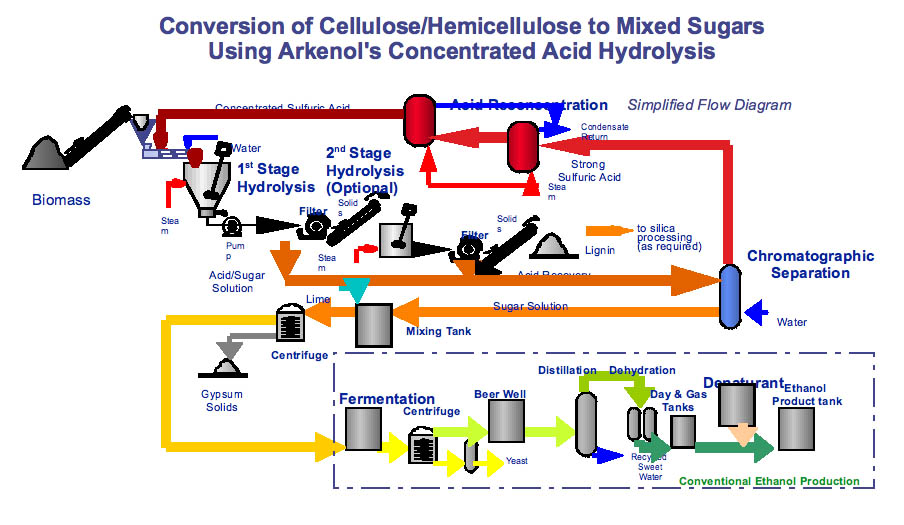

BlueFire Ethanol’s first cellulosic ethanol plant will be built in Lancaster, CA. BlueFire’s will use its patented Concentrated Acid Hydrolysis Technology Process to convert cellulosic waste ("Green Waste") into as much as 3.7 million gallons of ethanol annually. The raw material: energy plus urban, forestry and agricultural residues like rice straw.

BlueFire Ethanol is also one of companies with money from the U.S. Department of Energy to build a second planned ethanol production facility in southern California. It'll produce approximately 17 million gallons of cellulosic ethanol per year. Two factors in BlueFire's business plan: use waste to produce ethanol, not crops, and put the production near the end users. In this case, millions of Loa Angeles metro area vehicles.