Two green-tech startups capture the value of wastewater

Had the good fortune last week to interview individuals from not one but two technology innovators who have developed processes for bringing new value to wastewater.

The first, Ostara, is focused on recovering phosphorous and nitrogen -- which have enormous potential value in fertilizers but can be a huge problem when they reach excess levels in bodies of water. The Ostara Pearl process uses separate chemical reactions to recover these nutrients out of wastewater and create a slow-release fertilizer called Crystal Green. I'm simplifying things for the sake of the laypeople among us, including me.

The company's latest facility was opened at the end of May in Suffolk, Va. Managed in cooperation with the Hampton Roads Sanitation district, the facility will recover nutrients out of the Chesapeake Bay Watershed. Here's a statement from Ostara's president and CEO Phillip Abrary:

"Our technology integrates into the treatment system, processes the liquids from the solids recycle streams and recovers phosphorous and other nutrients, and then converts them into a high-quality environmentally friendly commercial fertilizer, increasing operational efficiency for the plant. This approach provides [Hampton Roads] with a cost-effective and environmentally sound operational improvement and also creates a fertilizer product made form the only sustainable source of phosphorous, waste, which is non-leaching and therefore helps protect waterways."

Abrary says the facilities Ostara creates aren't all that big; the new one in Suffolk has a 4,000-square-foot footprint, including three chemical reactors that are needed to recover the nutrients from the wastewater. That's about 5 percent of the size of a typical wastewater treatment plant, he says. The capital investment will be between 1 percent and 2 percent of the capital normally associated with a wastewater plant buildout, Abrary adds.

The project went ahead after success at the pilot scale; in that test, the Ostara technology recovered more than 85 percent of the phosphorous from the waste stream. The treatment plant where it has just deployed its technology can clean up to 30 million gallons of water per day. Ostara's first customer was the city of Edmonton in Alberta, Canada.

From the standpoint of the plant, the technology also helps with plant maintenance, since the organization was already responsible for figuring out how to discharge this waste: phosphorous and ammonia combine with magnesium to create something called struvite, which can clog pipes and be a drag on plant efficiency -- thus making it use more electricity. It's one of those vicious cycle problems.

So anyway, that's numero uno cool company to watch.

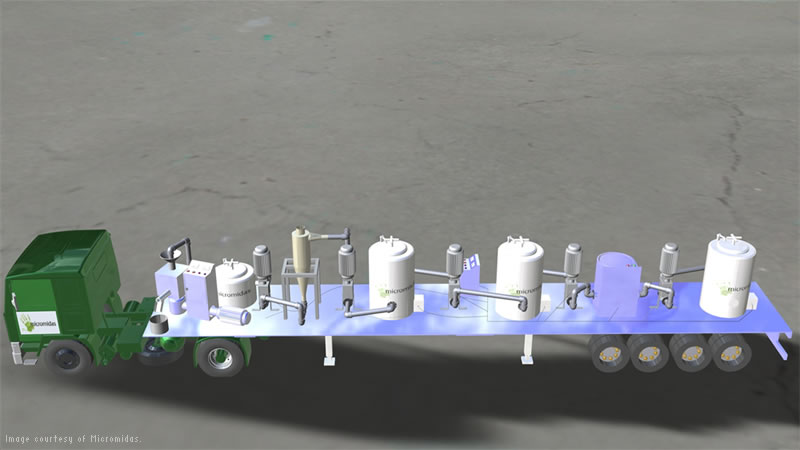

The second is one that I heard about through Autodesk with the imminently cool name, MicroMidas. As in, their technology turns one thing into another. (But not gold, folks.) This company is in a much earlier stage of its lifecycle than Ostara, and it is using Autodesk's software to help design and prototype its processing plants and equipment. Autodesk runs a Clean Tech Partner Program that arranges for green technology startups to earn "grants" of up to $150,000 of its software.

MicroMidas aims to use biorefinery processes to convert the organic part of wastewater into biodegradable bioplastics. There are more than 50 different machines that will be used in the process, and MIcroMidas is using Autodesk's Inventor and Algor Simulation software to figure out what's what.

John Bissell, CEO of Micromidas, which makes its home in Sacramento, Calif., say the Autodesk software has been instrumental in shaving the time off its development process. The company has even used the technology to create a pilot "refinery" which it will transport to different wastewater treatment facilities around the country for tests. "We are hitting our milestones exactly," Bissell says. "So, we probably wouldn't have made them otherwise."

The image shows what the Mobile Biorefinery lab looks like; it's the size of a typical shipping container. There should be one up and running for real within the next three months.