Drive giants plan next gen tech

Chip fabs aren't the only costly factories: next gen disks - which look to include self-assembling nanotech and frikkin' lasers - is going to be so expensive to develop that drive vendors have agreed to work together to bring it to market. Good for them - and good for us.

The problem: get magnetic disks to 10 terabits per square inch. There are promising approaches, but no proven manufacturable answer yet. This is the disk version of rocket science.

EEtimes reports that

Hitachi GST, Seagate Technology and Western Digital have agreed to form a group that will jointly conduct research and define a road map for hard disk drive technology. The group aims to end a long and heated debate about the next big leap in disk technology and is expected eventually to include all drive makers and their component vendors.

The big debate Hitachi GST, which includes IBM's former disk operations, wanted to push ahead with patterned media, which, as the name suggests, places nanoscale patterns on the disks. Seagate, the big kahuna in disks, wanted to go ahead with HAMR - Heat Assisted Magnetic Recording.

Both sides fought for their preferred approach, but its been clear that both are really, really hard. We need to do both to keep disk areal density growing at a Moore's Law-like 40% annual growth.

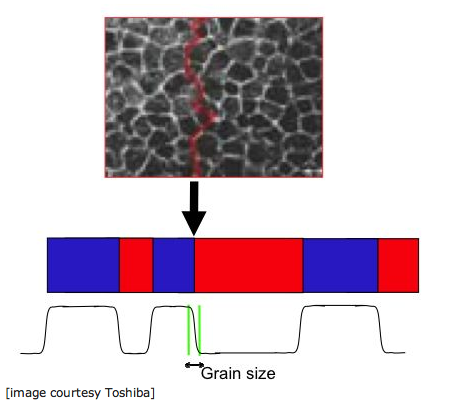

Today's magnetic media look like this:

As track size approaches the magnetic grain size, the track starts to bounce around - making it hard to read and write data.

Patterned media fixes that problem by placing the grains in regular order:

The problem: how do you make the patterns on more than 2 billion disk sides a year?

HAMR Heat, magnetize, cool. Repeat a billion times a second. That makes a strong magnetic charge. The problem: how do you heat a very small area very quickly?

Lasers, of course, but at gigabits per second this is no easy task. And there is the heat dissipation problem.

The Storage Bits take The disk industry faces huge problems in continuing to increase areal density. Solving the problems in the lab is one thing, but manufacturing over 500 million drives a year using this technology requires incredibly exacting mass production.

If they fail, our ability to keep saving more data at ever lower costs is gone - perhaps forever. Let's hope this ambitious effort succeeds.

Comments welcome, of course.