General Electric on 3D printing: 'We are on the verge of the next industrial revolution'

NEW YORK — It's not every day you get a 20-year-old Indonesian student outsmarting some of General Electric's greatest minds and designers.

According to GE's general manager for technology Christine Furstoss, the unnamed student helped General Electric save considerable sums of money in development and manufacturing costs by designing a critical aircraft part that was 83 percent lighter and yet still met the safety and design criteria.

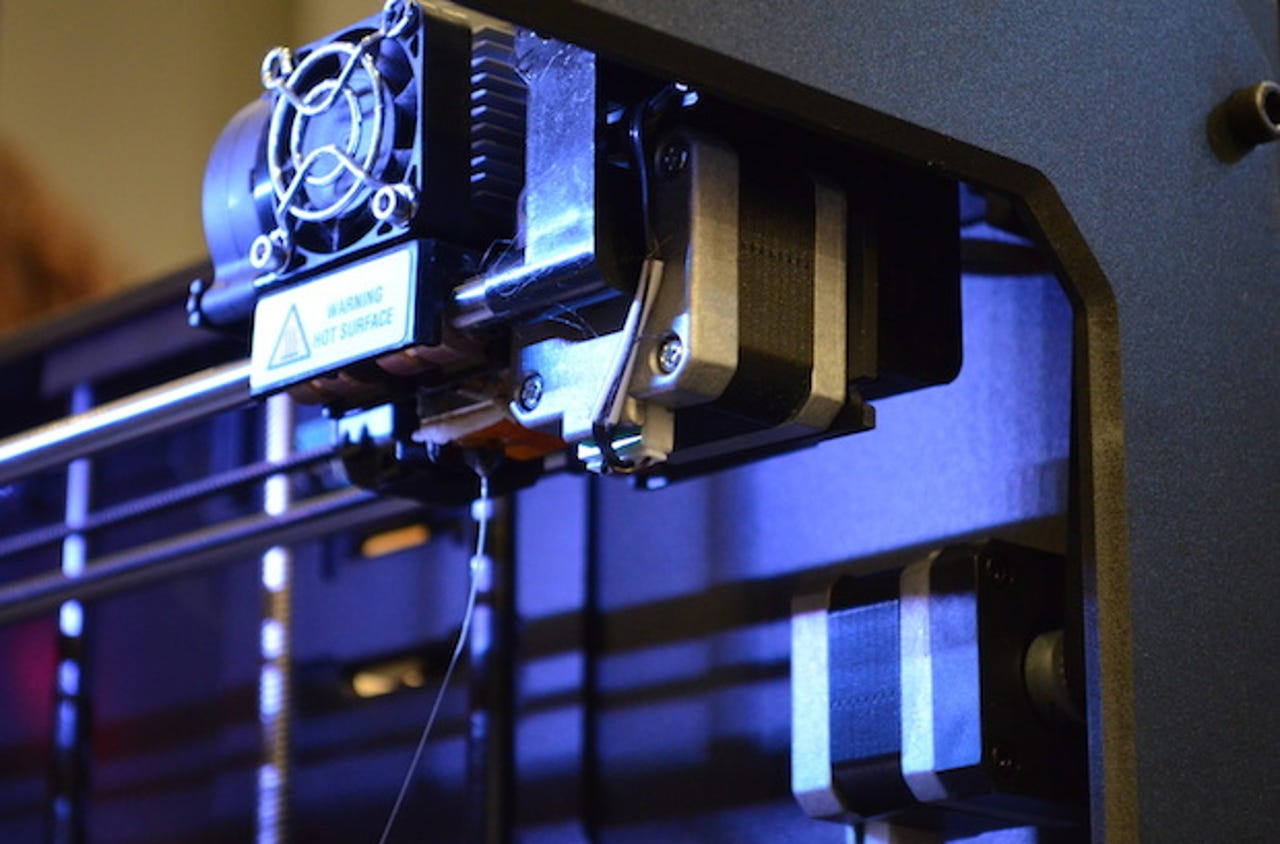

And that's all thanks to 3D printing. While it may be today's buzzword, in reality it's just a fraction of the overall manufacturing process — and General Electric wants to lead the way.

But it can only do that by embracing change and its desire to learn.

Furstoss told attendees at the Inside 3D Printing conference in New York on Thursday that the "maker movement" is revolutionizing how the traditional manufacturers look at their own design and building process — showing everyone how anything can be developed and built in a fraction of the time.

The Fairfield, CT-headquartered conglomerate has been pushing hard in the 3D printing and the next-generation manufacturing space.

The company built its own Rapid Prototyping Center in Louisville, KY in mid-July 2013, which has helped the company generate quick and easy feedback in the development process, and has been able to reduce costs by 80 percent on average overall. And in 2012, GE Aviation was formed from the acquisition of Morris Technologies, as the company wanted to learn more about additive manufacturing.

But Furstoss admitted that the company — and others — can and should be doing more.

"Additive manufacturing is not just another way to produce parts," Furstoss said. "It's a way to change how I work. It's a way to say, I can introduce products faster than ever before. Why? Because additive manufacturing gives me the opportunity to conduct faster prototyping. And it's also about learning and gathering data. And I can also make tooling that can use more conventional manufacturing."

"It's not just about making a final part, but that whole process makes you more competitive," she said.

In simple terms, the design and drawing processes is accelerated because the prototype design can be printed sooner rather than later. That allows designers to go back to their designs, modify at will, and ultimately that makes the manufacturing process quicker, meaning innovative new designs can be kicked out the door significantly faster than other traditional businesses, which makes the market more competitive.

More from ZDNET's coverage of Inside 3D Printers in New York City

As the company continues to learn about the capabilities and advantages that 3D printing has to offer, it's invested in more than three-hundred 3D printers across the company, which helps it to learn how to develop the more difficult or traditionally expensive parts for aviation, oil and gas, healthcare, and other businesses the firm has investments in.

Furstoss said by 2020, the company aims to print more than 100,000 parts for aviation. In the meantime, the company continues to focus on transforming its repair processes for industrial components.

"3D printing is not just used to prototype," Furstoss said. "But it's really important for us to use this technology to innovate and create products that could not be made in any other way."

"This is the opportunity we can't waste," she said. "It's about ecosystems, and learning, and we need to figure out what our role is, and if we are investing as much as we should be."