Ways to improve device backlighting described in new BlackBerry patent app

Technology described in a newly published BlackBerry Patent application would improve the quality of BlackBerry device backlighting by using "hot spot filters" to better managing overly "bright spots."

The Patent app, 0070291507, is entitled, Method and Device To Improve Backlit Uniformity.

The Abstract explains the basics:

A hot spot filter for a light guide is created by taking an image of the light output pattern of an illuminated light guide. The hot spot filter may be a film, a layer, or an additional liquid crystal display dedicated to attenuating bright spots from the light guide. The hot spot filter may be incorporated into the image display by adjusting the grey scale of individual pixels to provide sufficient compensation.

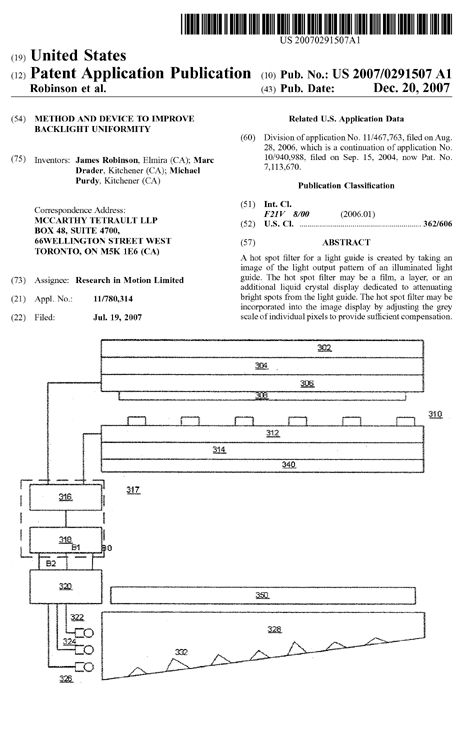

Figures 6 and 7, along with the accompanying documentation, offer details about how this hot spot filter might work. Let's go there now.

FIG. 6 illustrates an embodiment of a method for creating a hot spot filter for the light guide.

The light guide is illuminated to provide a light output pattern by an individual LED (e.g., white, red, green, or blue) or a group of LEDs representing a colour in step 602. The light output pattern may be optically processed.

This light output pattern is captured as an image by a light-capturing device, such as a camera 604. The captured image may be used to make a mask 606. This mask, in turn, is used to form the hot spot filter 608.

For example, the mask may contain apertures shaped and sized to conform to the hot spots. The mask may be laid over or upon a substrate, such as a plastic or glass film, and a coating or printing process deposits reflective and/or absorptive material onto the substrate through these apertures.

After further processing (e.g., heating, drying, ultraviolet or infrared curing), the substrate is ready for disposition over the light guide in the finished product.

The image capturing process may be performed from an actual handheld wireless device that is opened to expose the light guide. In such case, the camera may be disposed at a distance corresponding to that of the LCD's location within the finished product.

This image capturing process may be performed once per batch or at a designated sampling rate to account for component devices from batch to batch.

Now, if you are still w/me, we are ready for Figure 7:

FIG. 7 illustrates another method for creating a hot spot filter.

In FIG. 7, a colour grey scale compensation map is created for each color of light illuminating the LCD. First, one of the colours is selected 702 in which light of that colour illuminates the light guide 706.

The image from the light guide for that colour is captured 708. The captured image is processed to form a compensation map 710 to eliminate hot spots through use of the hot spot filter.

In this case, the hot spot filter may be a film or layer (350 of FIG. 3) upon which printing or coating of the hot spot areas is performed, may be such printing or coating directly upon the light guide, may be another liquid crystal display that is able to alter the pixel by pixel grey scale to compensate for any hot spots, or may be the primary LCD (defined by substrates 312 and 306 in FIG. 3) in which certain pixels are given an added darkened grey scale value for compensation.

The grey scale compensation map for the colour is stored in a suitable memory (e.g., the flash memory).

The method determines if another colour of LED is to be processed 714, 704. In this way, distinct image patterns may be obtained for each color of light generated by the light source.