Researchers develop printable rubber-like OLED displays

Researchers at the University of Tokyo have given new meaning to the term flexibility in the context of displays. They've developed of a stretchable display connected by organic light-emitting diodes (OLEDs) and organic transistors with a new highly-elastic conductor.

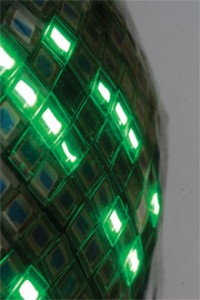

Credit: Takao Someya, the University of Tokyo

The rubbery display, pictured here on the left, can be stretched to 50% of its normal size, folded in half or crumpled up without incurring any damage, and can also cover complex three-dimensional objects.

As Technology Review writes, the technology can lead to displays and simple computers that you can wear on your sleeve, or wrap around your couch, or even serve as artificial skin for robots or prosthetic limbs.

Takao Someya, professor of engineering at the University of Tokyo, and his colleagues created the stretchy electronic circuits using a cheap industrial printing process by spraying carbon nanotubes with a fluoro-rubber compound. Unlike their previous conductor, the new version is significantly more conductive, can stretch to more than twice its original size, and can be printed, according to an article from Nature Materials cited in the Technology Review article. Plus, the printing is cheap, allowing for the organic transistors to cover a large-area and still operate efficiently.

The article offers a close look at how the intricate material is made:

Someya first combines carbon nanotubes with an ionic liquid--a liquid containing charged molecules--and a liquid polymer to make a nanotube-rubber paste. Then comes the crucial part: a high-pressure jet that spreads the nanotubes in the rubber. The jet makes the nanotube bundles thinner without shortening them and disperses the bundles uniformly in the polymer. "The longer and finer bundles of nanotubes can form well-developed conducting networks in rubbers, thus significantly improved conductivity and stretchability," Someya says. The jet process also increases the material's viscosity, making it suitable for high-definition screen printing.

The researchers use a printing mask to deposit 100-micrometer-wide lines of the conductor on a piece of rubber. Then they use the lines as a wire grid to connect organic transistors and OLEDs.

The current prototype is 100cm^2 (10 x 10), and contains 256 monochrome pixels (16×16 grid), but the research team is now working on improving the resolution and producing screens in color.

"A human-shaped display could be used to show medical diagnosis data, and there are various other applications," said Someya.