3D printing market set to rocket to $16.2B over next four years

At the rate the 3D printing is expected to grow over the next few years, its market value could be worth as much as $16.2 billion by 2018.

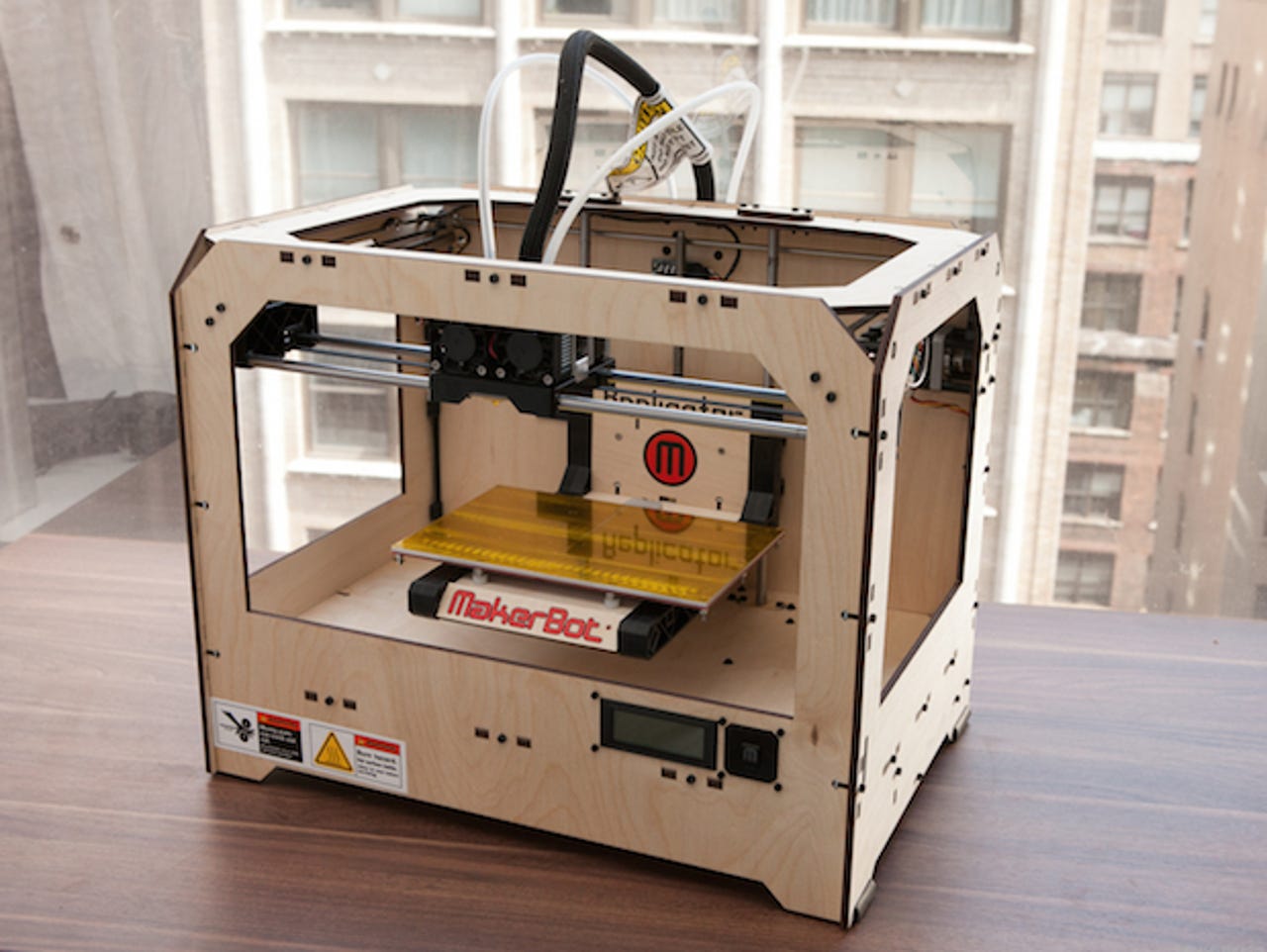

Featured

Latest research from Canalys says the overall market, including the 3D printing machines and the total cost of supplies and services, has already reached a $2.5 billion in 2013, and is expected to rise to $3.8 billion this year.

Canalys senior analyst Tim Shepherd explained that while this is a fast-evolving market, it's "still in its infancy."

"Expect to see new major entrants making a significant impact in the industry in the coming years, including giants such as HP," he said. "As barriers fall, new use cases emerge, the technology improves and new entrants join, this is a market that will look very different in five years' time."

According to the firm, the value of the 3D printer itself grew by 109 percent in 2013 to $711 million, and is expected to slow but retain strong growth to 79 percent this year to hit $1.3 billion.

In the short term, the research firm expects the market to become increasingly open to others as prices come down and the technology is refined.

Global 3D printing market | ||||

| Category | 2013 (est.) | 2014 (est.) | 2018 (est.) | Growth ('13-'18) |

| Total | $2.5B | $3.8B | $16.2B | 45.7 percent |

| 3D printers | $0.7B | $1.3B | $5.4B | 50.1 percent |

| Services, materials | $1.8B | $2.5B | $10.8B | 43.8 percent |

| (Image: Canalysis estimates, forecasts) | ||||