3D printing: Poor man's teleporter links Australia to the world

Many Valentine's Days ago, in an early display of what would today be called sexting, a college friend of mine cheekily took, developed and sent his girlfriend in Europe a card with a picture of a part of his body that one doesn't normally show in polite company.

By all reports, his Valentine's Day effort got the intended result, and all was good. However, in laughing modern-day recollection I recently wondered what the reaction would have been if he'd then had access to 3D printing technology of the sort that any Australian can now walk into Officeworks and purchase for $1499.

I am far from the first to marvel over the rapid consumerisation of 3D printing – it is mind-blowing stuff – and I admit to a certain prurient fascination with the reports of the many things that are being printed today: edible cakes and internal organs, for example. In a turn that would have Dr. Evil in ecstasy, there are even plans to use 3D printing to build a moon base.

Not since Star Trek in the 1960s has the world been so captivated by the idea of being able to instantaneously make something appear somewhere far away, seemingly defying the laws of physics. Speaking in terms of results rather than actual physical processes, 3D printing makes it possible – and it's going to see the world's manufacturers losing a small but significant part of their monopoly on the production of physical goods.

The potential for 3D printing to facilitate the delivery of certain products, such as smartphone covers and plastic action figures, will open up new micro-industries within the United States, where instantaneous delivery will be the only thing better than same-day delivery services from the likes of Amazon.com.

Overseas, however, 3D printing offers an even bigger promise, if only because physical distances mean the non-US world necessarily suffers a delivery-time latency for the transfer of any sort of physical object. No matter how urgent your package, getting Fedex, DHL, UPS, or any of the other companies to get it from the US to Australia, New Zealand, Chile or China is going to cost you – in both time and money.

Australians often speak of the 'tyranny of distance', referring to the logistical challenges imposed by large distances both inside and outside the country. That's why, in certain applications, 3D printing is going to become a game-changer.

Consider an Australian automotive-parts design firm that might be collaborating with, say, a German car maker to build specific auto parts together (with Australia's domestic car market evaporating, this is an increasingly likely scenario for the country's expert parts makers).

Design-focused firms already readily exchange 3D files online, but if they want to make the transition to a physical object the architectural firm would have to fabricate multiple proofs of concept in plastic; then courier them across the world to their collaborators; and repeat this process until both sides are happy.

It's a poor man's teleporter, and could significantly change the way firms in faraway countries interact with peers overseas. No longer will the tyranny of distance, and the tricky logistics it imposes, limit the creativity and innovation of collaborative teams.

With 3D printing, the architects could literally print their latest prototypes on a 3D printer in their clients' offices in Germany, allowing the manufacturing process to run during the European evening and the models to be ready to look at first thing in the morning.

Pick your work process; if it involves physical models, 3D printing will allow it to function faster and more efficiently. Australian consumers, too, will be able to purchase certain types of products online from anywhere in the world and hold them in their hands within hours.

It's a poor man's teleporter, and could significantly change the way firms in faraway countries interact with peers overseas. No longer will the tyranny of distance, and the tricky logistics it imposes, limit the creativity and innovation of collaborative teams; nearly instantaneous transmission of ideas will span continents and oceans.

Completing the puzzle

If 3D printing is the new output in this scenario, there is also a significant new input: 3D scanning. While 3D printing involves producing models from digital files, 3D scanning allows the production of digital files from physical objects – and it is this capability, if executed correctly, that will bring 3D production processes to the mass market.

3D scanning isn't completely new, either, but the apparatus for doing 3D scans of small objects has traditionally been large, clunky, and complicated. The crew in Prometheus used rather impressive autonomous drones with 3D scanning to map out the inside of an alien structure that would form the setting for the movie's disappointing plot, but Australian research organisation CSIRO has made the technology more accessible with the compression of LIDAR 3D-scanning technology to handheld-sized Zebedee units that will let Queensland Police scan crime scenes in minutes.

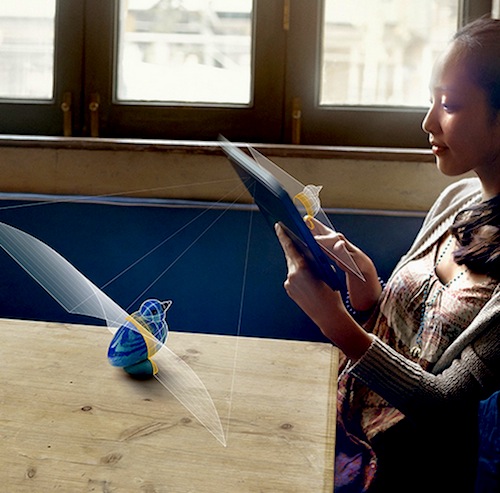

The push to consumerise such technology had borne little fruit until the introduction of Intel's RealSense technology at CES last month. RealSense will eventually bring a whole new dimension – literally – to the way we interact with our mobile devices by giving them a standards-based, accessible platform on which to incorporate 3D gesture recognition and 3D object scanning capabilities.

3D sensing will help equipment makers fill out the 3D story that they started with the introduction of accessible 3D printing. Rather than using 2D photographs to exchange information about things, we'll be able to use 3D models instead.

Throw in handheld holographic projectors in five years or so, and we'll have the ability to scan objects in three dimensions and make them appear in physical or holographic form anywhere in the world – instantaneously. Cue FaceTime 3D, Instagram 3D and, yes, even Fruit Ninja 3D.

After years of being stuck in the collective sci-fi imagination, the commoditisation of scanning and printing devices has finally established a vocabulary for the consumer world's move into full 3D interaction. We're not completely there yet – 3D printer makers still need to juggle cost and quality to striate their product offerings and bring down the entry price by a factor of ten – but knowing the industry's penchant for integration, it can't be too long coming.

Actually, on second thought, it might be good to wait a little longer. While nobody knows where convenient 3D printing and scanning will take the world now, had it been available those years ago I can only imagine what my college friend's girlfriend might received on that Valentine's Day. Perhaps, sometimes, it's better that progress like this takes time.

What do you think? Are 3D printing and scanning going to be transformative like this? Or will they fizzle and disappear like so many novelties before it? How would you use them – or how are you using them already?