Fictiv looks to speed up 3D printing, CNC machining development cycles

Eyeing room for innovation within the manufacturing space, the three-year-old company Fictiv is officially launching its hardware development platform on Monday. With a vetted network of 3D printing and CNC machines, Fictiv is aiming to bring the development cycle down from weeks to days, for startups and large enterprises alike.

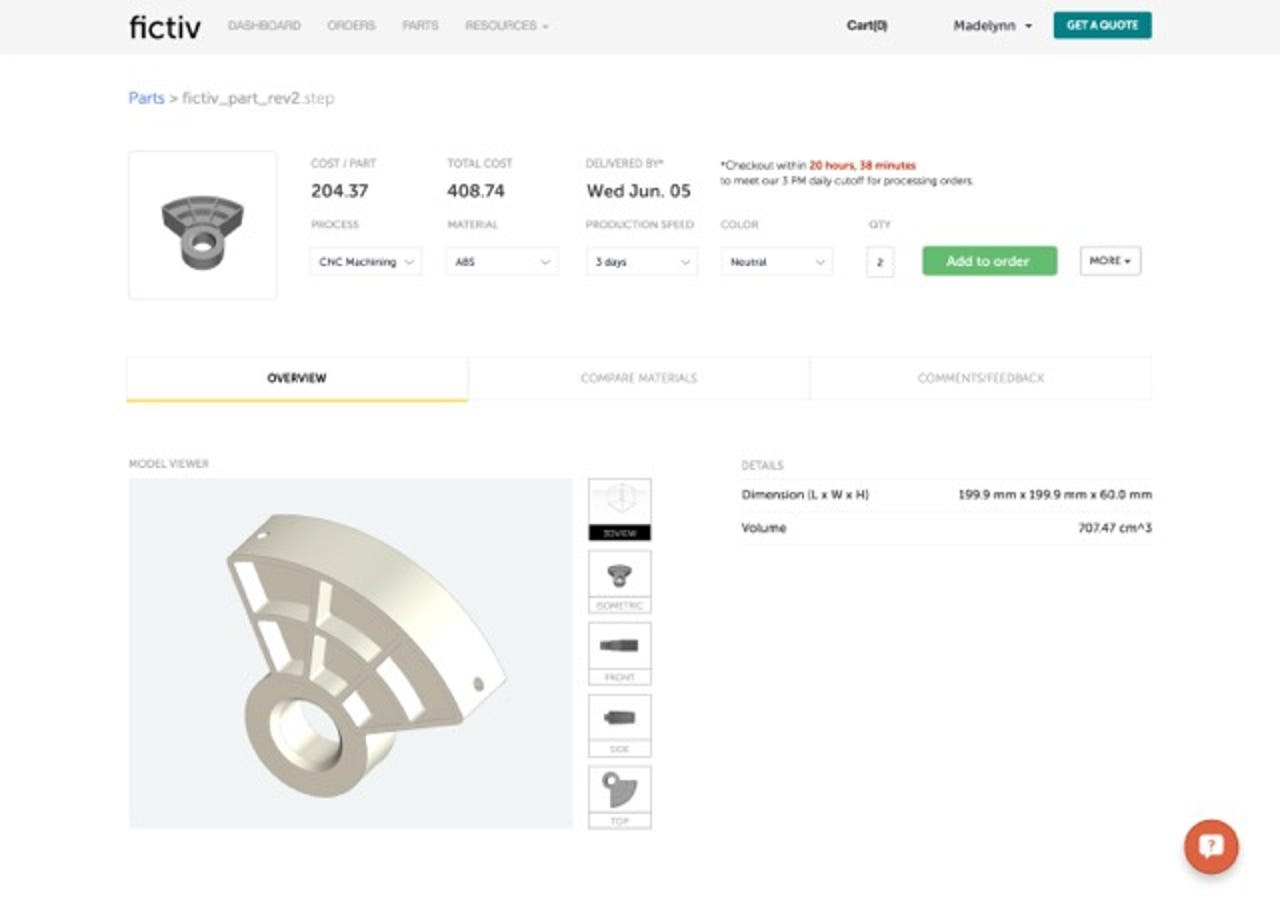

Fictiv's online interface allows engineers and designers to upload a CAD design, get an instant quote and place orders. After an order is placed, Fictiv's platform matches each part to an immediately available machine among its network of vendors. This doesn't just reduce the time it takes to fabricate a part, but it also allows small machine shops to increase the number of parts produced on their machines.

"Our vision is to democratize manufacturing and give people better access to tools," said Dave Evans, who founded Fictiv with his brother Nate Evans.

By empowering smaller machine shops, Fictiv is using its network to go up against big players already providing on-demand 3D print services, like Proto Labs and UPS. Just last month, UPS announced it has partnered with SAP to launch a distributed, on-demand manufacturing network based on 3D printing. The service combines SAP's extended supply chain software with UPS's 3D printing machines and logistics network.

While that makes UPS a competitor for Fictiv, Dave Evans said the UPS development "gets us excited about the ecosystem, that there's real demand here to try to get better utilization out of these machines."

Now with the added capability of CNC machining, the Fictiv platform is ideal for an emerging technology company like Hykso, which builds sensors used in martial arts. The company will use 3D printing to iterate different designs and will use CNC machining when it's ready to produce the actual figures. The platform saves Hykso time -- the company actually cut its development process by 39 days -- by allowing it to manage all of its manufacturing needs through a single service.