The fascinating science of Gorilla Glass

Bryan Gardiner wrote an amazing article for Wired that explores the creation and history of Gorilla Glass. Glass Works: How Corning Created the Ultrathin, Ultrastrong is an excellent read, especially if you own an iPhone.

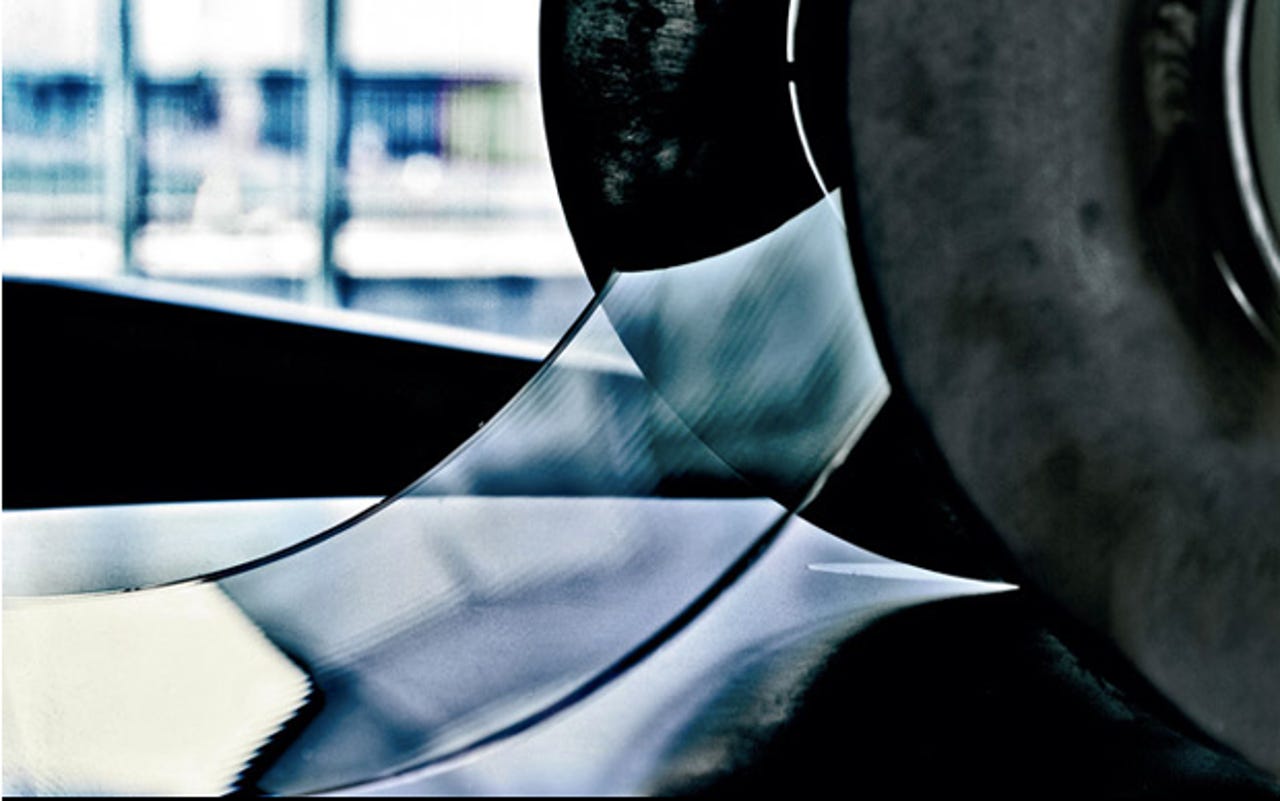

The ubiquitous glass -- found in the iPhone, Galaxy S3 and Lumia 900 -- was born out of an R&D project at Corning that looked for ways to leverage its experience in making strengthened glass. The breakthrough occured when Corning discovered that adding aluminum oxide to its glass composition before bathing it in hot potassium salt created glass with unmatched strength.

Gorilla Glass 1.0 is able to withstand 100,000 pounds of pressure per square inch wheras normal glass can handle about 7,000 PSI. A 1-mm-thick piece of today's Gorilla Glass 2.0 (believed to be what's included in the iPhone 5) can withstand 2 joules of energy from an impact hammer without shattering.

Here are some other interesting nuggets from the article:

Corning's first synthetic glass-ceramic, dubbed Pyroceram, is lighter than aluminum, harder than high-carbon steel, and many times stronger than regular soda-lime glass. Pyroceram eventually found its way into everything from missile nose cones to chemistry labs. It could also be used in microwave ovens, and in 1959 Pyroceram debuted as a line of space-age serving dishes called Corningware.

In 1962 Corning marketed its new glass to manufacturers of phone booths, prison windows, and eyeglasses as Chemcor, but it was recalled for fear of the potentially explosive breaks. Chemcor seemed liked a good fit for car windshield (it briefly appeared in some AMC Javelins) but the added cost was a deal breaker for auto manufacturers. It didn’t help that crash tests found that "head deceleration was significantly higher" on Chemcor windshields, meaning that windshields would remain intact, but skulls would not. The product, known internally as "0317," was put onto a shelf in 1971 until a more practical application could be found.

In 2005 Corning revisited its 4mm thick Chemcor samples when Motorola released the Razr V3 flip phone. Instead of high-impact plastic, the V3 featured a glass screen which set the wheels in motion. Corning revived "0317 and the project was codenamed "Gorilla Glass." In February 2007 Steve Jobs asked Corning CEO Wendell Weeks if he could create millions of square feet of 1.3mm thin, ultrastrong glass in six months.

The problems were numerous. Chemcor had never been mass-produced on that type of scale and it wasn't known if it could be made ultrathin and still retain its strength. Suffice it to say that the little company from Harrodsburg Kentucky had a huge hit on its hands. Corning’s Gorilla Glass revenue skyrocketed from $20 million in 2007 to $700 million in 2011 and it plans on releasing an even stronger version 3.0 "early next year."

The article is an excellent read, and highly recommended.