Wave disk engines to make hybrid vehicles cheaper, more efficient

Researchers from Michigan State University and the Warsaw Institute of Technology are developing a wave disk engine and electricity generator that promises to be five times more efficient than traditional auto engines in electricity production, 20% lighter, and 30% cheaper to manufacture.

The new hyper-efficient engine is about the size of a large cooking pot, and could replace current backup generator technology of plug-in hybrid electric vehicles, according to Green Car Congress.

The idea may not be far-fetched as the team, led by Norbert Müller, an associate professor of mechanical engineering, has recently been awarded $2.5 million from the Department of Energy’s ARPA-E program to begin work on a vehicle-size wave disc engine/generator that could be ready in two years.

How do wave rotor engines work?

The wave disk engine is a new implementation of wave rotor technology (think micro turbines). The first successful realization of a wave rotor was developed in the mid-1950s.

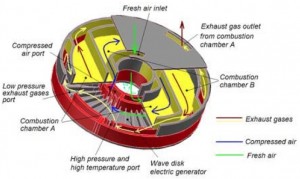

Wave rotors (also called pressure wave machines or pressure exchangers) are unsteady-flow devices that utilize shock waves to transfer energy directly between a high-energy fluid to a low-energy fluid, thereby increasing both temperature and pressure of the low-energy fluid.

According to a paper published by the MUS and Warsaw scientists in 2004, wave rotor technology can enhance cycle power and efficiency, plus possibly reduce the overall size, weight and cost. It allows a higher cycle peak temperature without need for a cooling system. Additionally, the rotational speed of a wave rotor is low compared with turbo-machines, resulting in low material stresses.

The new wave disk has a leg up on earlier wave rotor implementation that were mainly axial flow. In axial-flow configurations pure scavenging (the process of returning the hot compressed air back to the turbine) is a challenging task. Although it's possible to achieve a full scavenging process for both through and reverse-flow configurations, the solutions lead to more complex configurations.

The wave disc technology, however, uses a radial and circumferential flow, which can substantially improve the scavenging process by using centrifugal forces. Compared with straight channels, curved channels provide a greater length for the same disc diameter, which can be important to obtain certain wave travel times for tuning. (Another paper, published in December 2008, explores this topic in detail.)

Previous research by the MSU team led them to position the combustion process internally in the wave rotor, thereby simplifying porting between the turbo-compressor and the wave disc “enormously”. That led to a proposed concept of a Radial Internal Combustion Wave Rotor—the precursor to the wave disk engine.

Now, with the wave disk engine, Norbert Müller's goal is to: "Enable hyper-efficient hybrid vehicles to meet consumer needs for a 500-mile driving range, lower vehicle prices, full-size utility, improved highway performance and very low operating costs. The WDG [wave disk generator] also can reduce carbon dioxide emissions by as much as 95 percent in comparison to modern internal combustion vehicle engines."

View the video below to hear Norbert Müller describe his wave disk generator.