Chris Anderson: Why I left Wired - 3D Printing Will Be Bigger Than The Web

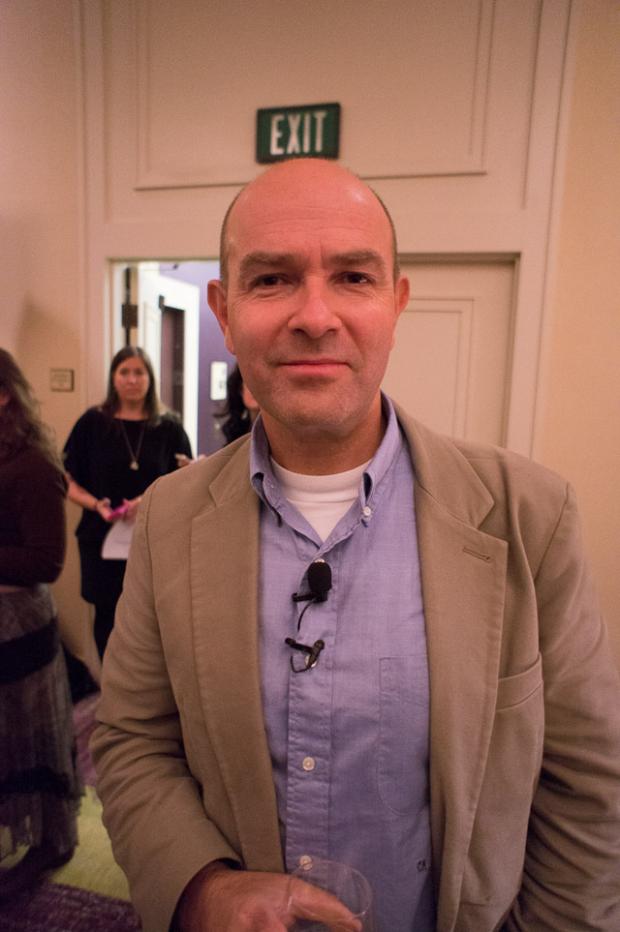

Chris Anderson has exited one of the top jobs in publishing - Editor-in-Chief of Wired magazine - to pursue the life of an entrepreneur, making a big bet that 3D printers represent a massive new phase of the industrial revolution.

He spoke at a Wired "Culturazzi" event, at the Marriott Union Square and to sign copies of his latest book: "Makers: The New Industrial Revolution."

I'd have pinned the start of the Industrial Revolution to the invention of the steam engine and its ability to power large numbers of machines thus enabling the first factories - which represented aggregated labor energy. Scale makes factories viable.

But I can see why Mr Anderson would favor the Spinning Jenny as it was a high-tech machine that was kept in a home - just as 3D printers are home based, completing a neat cycle of history.

He spoke about the invention of "desktop publishing" when laser printers, combined with software such as Adobe Pagemaker, revolutionized the publishing industry. You no longer needed a massive print "factory" and deal with unions, you just clicked a button on your screen, "Print." A massive industry had been reproduced as a simple icon.

And that's what 3D printers represent, nothing less than the consolidation of the massed factories of the industrial revolution, into a singe icon on your computer's screen: "Make."

This is the promise of 3D printers, they are "replicators" they enable us to photocopy reality: "Rip. Mod. Make."

They represent the next industrial revolution and it's because of this that Mr Anderson left his job. "It will be bigger than the Web," he predicted.

At the book signing, I asked Mr Anderson how he was going to profit from 3D printers, will he make them? No, no, he has his drone company, which he says is the same thing, and that he explains in the book. Making robotic flying gizmos. I don't quite understand how it is the same thing but for the purposes of the evening's theme, it is the same thing.

I must admit I don't understand how printing plastic things at home disrupts anything beyond my local "99 cent" store that has lots of plastic things that now I might choose to print at home, and it would probably cost me more than 99 cents - given the history of ink prices for my home printer.

Our industrial age has created a massive number of advanced materials that are essential to producing our products - 3D printers can only handle soft, easily melted materials. A home 3D printer that can create a product with multiple materials, such as ceramics and metals, hasn't been invented and won't be for many years.

How disruptive can a 3D printer making plastic things be? Mr Anderson's book was printed at a large print shop - my home printer, despite many years of progress, still can't replicate a book - in all its qualities of heft and form.

If 3D printers could handle melted cheese, sugar, or chocolate, I could see a future for them in the home. But I wouldn't leave my day job.

More photos:

Above, Katie Boysen, Communications Director at Nasty Gal.

More photos here.