Embedded sapphire and Liquidmetal could arrive in iPhone 6

The U.S. Patent and Trademark Office on Tuesday granted Apple patent number 8,738,104 for "Methods and systems for integrally trapping a glass insert in a metal bezel."

Featured

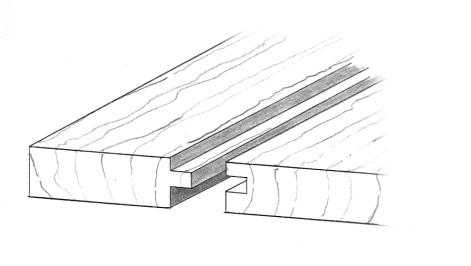

The patent describes a process by which a device's display is fused with the body (sometimes called the "frame" or "bezel"). The new process involves integrating the display (more on that in a second) into a groove along the inside of the bezel, conceivably to create a thinner, more streamlined design. Imagine a process like that of tongue and groove flooring, where pieces interlock into each other, below the surface. The result is smooth, yet extremely strong.

In the current iPhone 5s the glass and the aluminum bezel are separate pieces and the glass rises above the edge of the device, as can bee seen in its profile view. The iPhone 5 is visibly thinner, partially because of the device's "chamfered" (or beveled) edge.

The photo above (courtesy of iMore) shows the difference in thickness between the iPhone 4 and iPhone 5, where Apple made a big reduction in overall thickness. It stands to reason that its new patent could result in an iPhone 6 that's even thinner than the current iPhone 5s.

A recent mockup of the iPhone 6, courtesy of macitynet.it, shows how much thinner the iPhone 6 could be when compared to the current iPhone 5s.

The new Liquidmetal and sapphire process could allow Apple to manufacture much thinner devices. According to the patent:

"The formation of a bezel around a glass member substantially eliminates tolerance issues associated with the bezel and the glass member. Because the material (e.g., metal) used in the bezel is provided in liquid form around the glass member, there is effectively no tolerance that has to be maintained with respect to the bezel. The liquid flows around the edge of the glass member, and when solidified, effectively grabs and adheres to the glass member."

Current iPhone screens are manufactured from Corning's super-strong Gorilla Glass, but the patent mentions that "a suitable transparent material may include any synthetic transparent material, as for example, synthetic sapphire" (emphasis mine). You'll recall that Apple acquired three years worth of the supply of sapphire screens from manufacturer Canonical in February 2014.

As for the bezel itself, it appears that Apple may be finally using the LiquidMetal technology that it licensed in August 2010 and renewed last week. According to the new patent, Apple could bind a Liquidmetal bezel to a sapphire glass screen in a future Apple device. The result could be a seamless design the reduces thickness and benefits from the fused bezel and screen.

The patent's abstract reads:

"Methods and apparatus for creating an overall assembly formed from a transparent member and a metal member are disclosed. According to one aspect of the present invention, a method includes positioning a transparent member in a mold configured for insertion molding, and providing a liquid metal into the mold. The method also includes hardening the liquid metal in the mold. Hardening the liquid metal includes binding the metal to the transparent member to create the integral assembly."

While thinness and strength will be positive benefits for a future iPhone (or iPad), it could come at the expense of repairability. When Apple moved away from screws and began bonding MacBook displays to its aluminum bezel with glue, the resulting display was a single part that had to be replaced entirely in the event of a crack or a chip in the glass.

The same could be the case with a sapphire glass and Liquidmetal-based device – it would be thinner, but might require an almost complete replacement if damaged.

Kyle Wiens of iFixIt had this to say about Apple's newest patent:

Integrating the display assembly into the frame of the phone will likely make it more expensive to repair. Upcoming green cell phones standards will require more modularity for ease of repair and recycling, and it will be interesting to see whether this design is compliant.

I think it's possible for Apple to make an elegant, slim phone that is repairable.

An unfortunate side effect of patents like these is that in addition to preventing competitors from copying Apple's hardware, they can also prevent independent companies from producing compatible parts.

As devices get more integrated, it illustrates the need for electronics companies to sell service parts to consumers. The design of the next iPhone is an opportunity for Apple to show that their environmental claims are more than skin deep.