Plastic electronics factory gets funding

A UK company has announced it will build a factory to produce flexible display technology components for use in commercially available e-paper products.

Cambridge-based company Plastic Logic has secured $100m (£51.2m) worth of venture capital to build the factory in Dresden, in an area of Germany known as "Silicon Saxony".

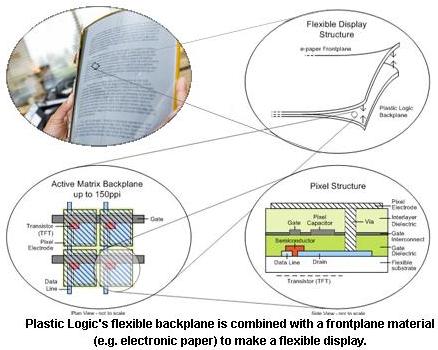

The factory, due to begin production in 2008, will manufacture flexible active-matrix display modules for electronic reader products. An active-matrix is an array of pixel electrodes, where the voltage on each pixel is controlled by an active electronic component, usually a thin film transistor (TFT), and by the signals on an array of intersecting row and column electrodes.

Plastic Logic's organic TFTs are embedded within layers of conducting, semiconducting and insulating polymer materials. These materials can be deposited from a solution allowing the devices to be "printed". Polymer materials are also flexible, allowing the production of lightweight, portable displays.

Plastic Logic uses a substrate of polyethylene terephthalate (PET) as a base layer for the display, and a variety of printing and direct-write techniques — such as the use of lasers — to pattern the polymer materials.

"It's much more like printing than silicon production," Simon Jones, vice president of product development for Plastic Logic, told ZDNet UK. "Silicon is produced at high temperatures and in vacuums — this [organic polymer production] is a low-temperature process and minimises the use of vacuums."

Jones would not give exact details of how the Plastic Logic organic polymers work.

"That's the clever bit — there's clearly some clever chemistry going on. It's a very proprietary technology that we've developed, and we're not going to divulge that to anyone," said Jones.

Jones sees two main applications for flexible plastics technologies — radio frequency identification (RFID) tags and flexible displays. He claimed that displays are one of the key initiatives for the technology, as current displays are power-hungry and so eat into the battery life of mobile devices, and use heavy materials, limiting portability.

Plastic Logic was originally spun out of the prestigious Cambridge University Cavendish Labs. Founded by Sir Richard Friend and Henning Sirringhaus, the company was not set up initially to manufacture plastics electronics products.

"We have investors that expect us to be aggressive," said Anusha Nirmalananthan, marketing executive for Plastic Logic. "They expect us to become manufacturers."