Regenerating plastic can patch bullet holes

Researchers have devised a new chemical concoction that can repair damaged plastics like never before. Until now, the self-healing properties of polymers have been limited to microscopic defects only, like cracks as wide as hair. The new system paves the way for synthetic materials capable of filling large holes after ballistic impacts -- or maybe even big cracks on airplanes and spaceships midflight.

Liquid mixtures of specific organic molecules have been known to quickly form solid structures when combined. But the challenge has been finding a way to deliver liquids to punctured sites and have them stick around long enough (without leaking away) for chemical reactions to occur and solidify them in place.

So, a team led by Scott White from the University of Illinois, Urbana-Champaign, developed a vascular system to deliver those raw ingredients to holes in polymeric materials. They created a network of channels filled with those restorative liquids, allowing them to run through plastics like arteries and veins. It basically works like a blood clot.

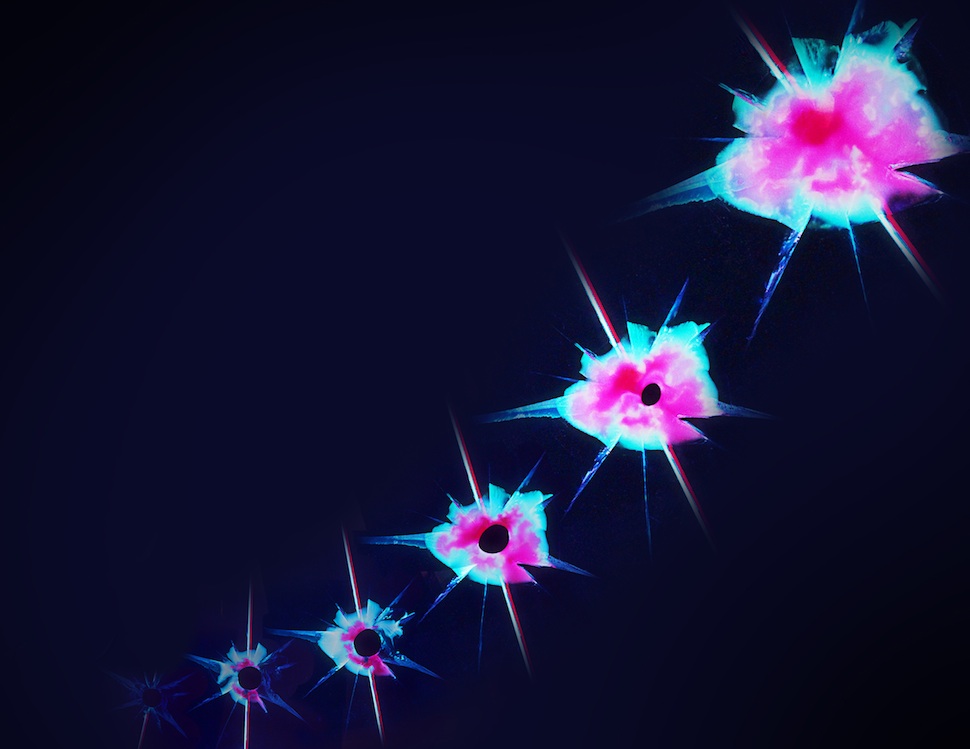

Two reactions need to happen, and timing is everything. First, the liquids have to mix to form a gel at the site quickly, but it also has to allow enough time for the second, slower polymerization reaction to take place. Pictured above, a time sequence showing an impact-damaged specimen undergoing the restoration process.

- They embedded the 330-micrometer-diameter channels into a plastic sheet. Then punctured it.

- When the damage occurs, the channels rupture and the regenerative chemicals are delivered through two isolated fluid streams (dyed red and blue) that infiltrate the cracks, wetting the inner surface of the damage.

- The mixing of the liquids immediately forms a semisolid gel, creating a scaffold for continuing the delivery of the restorative chemicals.

- After the damaged region and the cracks are filled, the gel hardens into a rigid polymer to create a seal, and the material goes back to its original function.

"What we did here was what I like to call repair by regrowth," Illinois's Jeffrey Moore tells Science. Their network of capillaries filled holes that were nearly a centimeter in diameter -- with cracks radiating out more than 3.5 centimeters (just over an inch). That's about 100 times larger than any such previously self-repaired defect, he adds. The holes were filled in about 20 minutes, and the gel continued to solidify into a hard plastic for three hours.

They tested the system using a 9 millimeter bullet and a thin epoxy sheet. Sure enough, the system autonomously replaced mass that was lost from the ballistic impact. The team envisions commercial plastics and polymers embedded with vascular networks that are filled with regenerative agents ready to be deployed whenever damage occurs -- just like biological healing. Self-repair capabilities like this would be very useful for commercial goods (like car bumpers) and also for parts that are harder to repair, like spacecrafts in orbit.

The work was published in Science earlier this month.

[AAAS, Illinois via Science, Nature]

Images: Ryan Gergely, University of Illinois (thumbnail) & Nathan Bajandas, Beckman Institute, University of Illinois (top, middle)

Related on SmartPlanet:

- Turning shrimp shells into plastic

- Smart, self-healing hydrogels act like velcro for sutures

- Spinning fishing line and sewing thread into artificial muscle

- Slug-inspired surgical glue patches up broken hearts

- Self-healing batteries could last 10x longer

This post was originally published on Smartplanet.com