3 robots build a chair: Turning machines into more human collaborators

The chair setup may seem like a straightforward problem, but it is devilishly complicated. Every action carries a series of consequences that could lead the collaborators to a dead end -- the way a robot grasps one of the parts limits the way another robot can grasp or work on that part, and robots in motion are collision-prone, so each position change alters the paths available to the other robots. But figuring out a workable solution to this problem will be essential to the evolution of automated manufacturing. The hope is that one day soon robots will be able to assess and execute complex tasks on the fly and without substantial intervention from human operators.

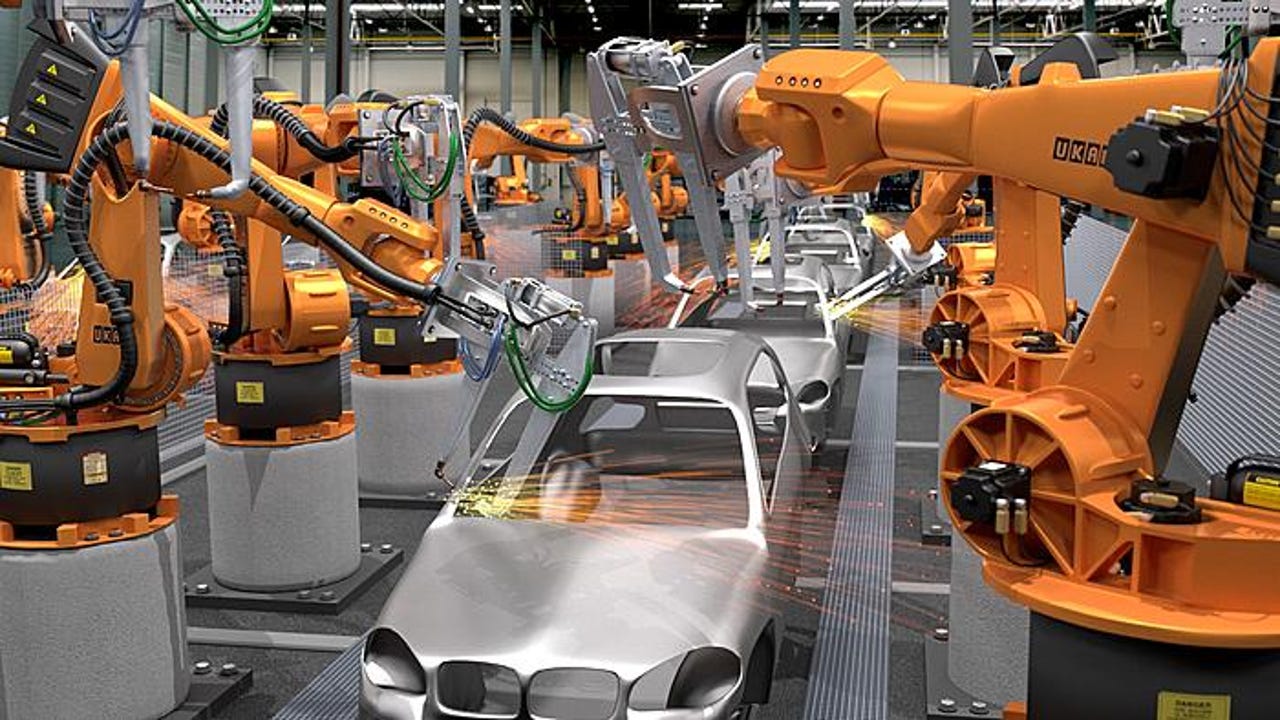

Robotics

In late May, a group of MIT researchers presented an algorithm at the Institute for Electrical and Electronics Engineers' International Conference on Robotics to address the collaborative assembly problem head-on. Their solution, which takes its inspiration from the way humans solve complex problems, earned them two nominations for best-paper awards and may be a crucial contribution to the future of the automation economy.

"We're really excited about the idea of using robots in more extensive ways in manufacturing," says Daniela Rus, a professor in MIT's Department of Electrical Engineering and Computer Science, whose group developed the algorithm. "For this, we need robots that can figure things out for themselves more than current robots do. We see this algorithm as a step in that direction."

The new algorithm starts out by making a plan that ignores difficult grasping problems that might arise. Essentially, the algorithm begins by treating each step as a discreet task that hasn't been limited by the grasping scenario introduced in the preceding step. In other words, it figures out how the robots would work in collaboration on each step as though that single step were the beginning and end of the problem.

Next, the algorithm works out how a single robot working on its own portion of each step might transition to the next step it's involved in. If the robot has a suitable grasping position to transition to that step without dropping the object, the algorithm adds that component to its attack plan. If not, it postpones figuring out how to make that transition. The algorithm then approaches the postponed transition problems by considering which of the other robots might be in position to lend a helping hand.

So far, this is a clever but relatively straightforward approach to systems-level automation. But the key to the algorithm's utility in future manufacturing scenarios is what it does when it encounters any remaining transition scenarios in which no grasper is available to ensure an efficient transition between steps. In a traditional approach, the algorithm would begin backtracking through the steps of its plan, revising the previous steps to try to find a workable transition. But each revision introduces new complexity to the problem, which greatly increases the processing time necessary to find an efficient way forward. With just three robots, the computing time necessary to work out an efficient plan can be hours, even days.

The team's answer is wonderfully human. The algorithm simply tells the robots to drop what they're holding, move into a more optimal position, and pick up assembly from that point. It may seem simple, but this is a radical departure from current automation solutions, where the objective is absolute efficiency. By making a plan pretty efficient but not rigidly so, the algorithm can be applied to complex manufacturing problems that currently can't be solved automatically. Since the dawn of factories, employers have tried to increase the efficiency of human workers by making them more machine-like. It's ironic, then, that a new algorithm enables robots to tackle problems in a messier and ultimately more human way.