Plasma thrusters for small satellite systems hit hyper drive

A company that makes propulsion systems for small satellites, Orbion Space Technology, has announced $9.2M in Series A funding. The round was led by Material Impact, a venture firm focused on translating early stage materials technologies into products and companies.

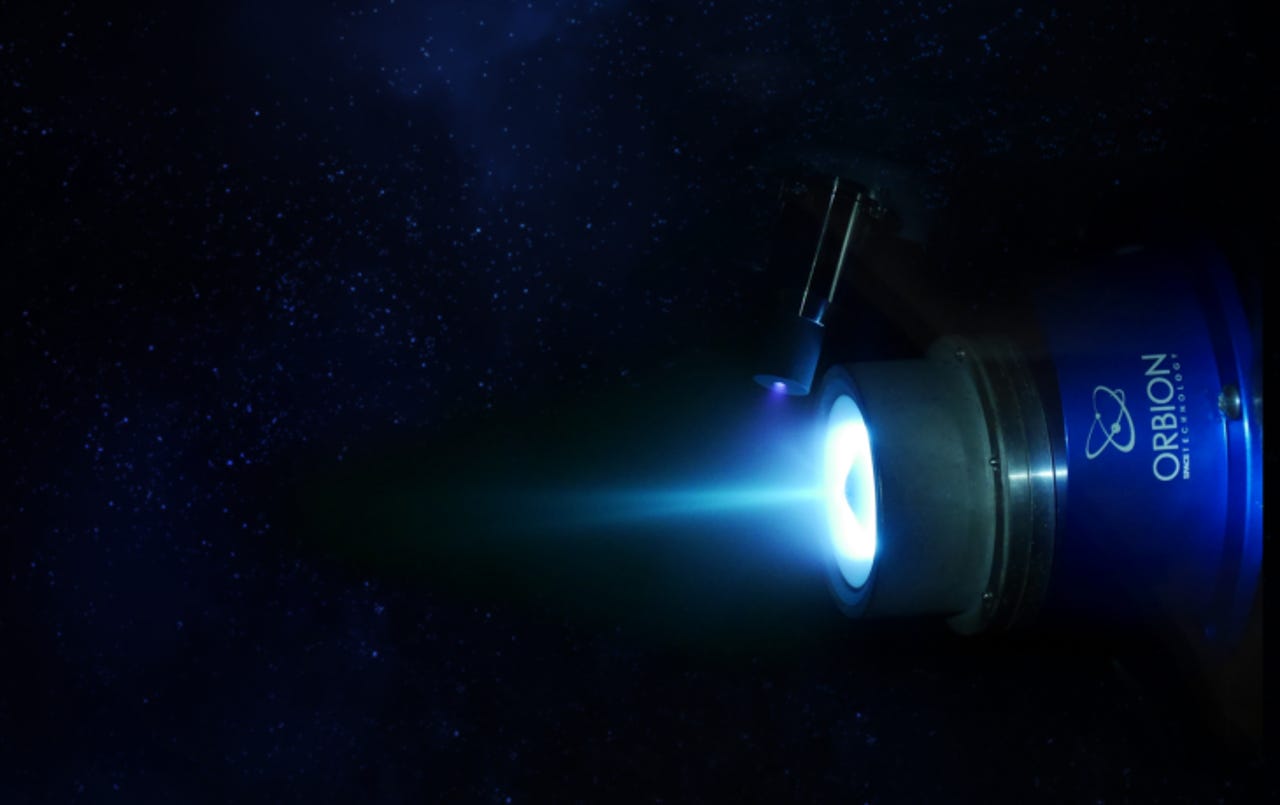

Orbion has developed a very Star Trek-sounding technology that may prove to be a crucial component of an emerging New Space industry, the first-ever Hall-effect plasma thrusters for small satellites, dubbed the Aurora system. The company plans to use the capital from this round to support mass production of its thrusters.

Hall-effect plasma thrusters are a type of ion drive in which a propellant is accelerated by an electric field. The technology has been around since the 1960s, and Hall-effect thrusters were in use on Soviet satellites between 1972 and 1990.

What's new is the size of the thrusters, as well as the size of the satellites they power, which are variously dubbed smallsats, microsatellites, or nanosatellites. As components and sensing technology has gotten smaller, and with the diversity of computing and sensing components available off-the-shelf, this new breed of satellite is cheap to build and lightweight, further reducing payload costs. That's opening up the possibility of launching communications and satellite arrays to companies and organizations that have never had that option.

"Many of the components on new small satellites, such as solar cells, batteries, and computers, can be leveraged from large established terrestrial markets and can easily satisfy the projected growth," according to a spokesperson. "Propulsion, however, is a "space-only" technology that has no terrestrial counterpart and, until Orbion, there was no supplier capable of delivering hundreds or thousands of thrusters for satellites."

That's put Orbion in a unique position to become a lead supplier in what's otherwise a highly fractured field. The company has set up an end-to-end manufacturing pipeline that includes robotic assembly-line integration and acceptance testing perfected in high-volume production environments. Interestingly, the model employs techniques and infrastructure developed in the tactical missile industry.

Dr. Brad King, CEO of Orbion Space Technology, says: "We're honored to have the financial support and expertise of such key investors as Material Impact to power our progress. It's an exciting milestone in our mission to bring modern mass-manufacturing to space technology and help New Space operators unlock their full potential."