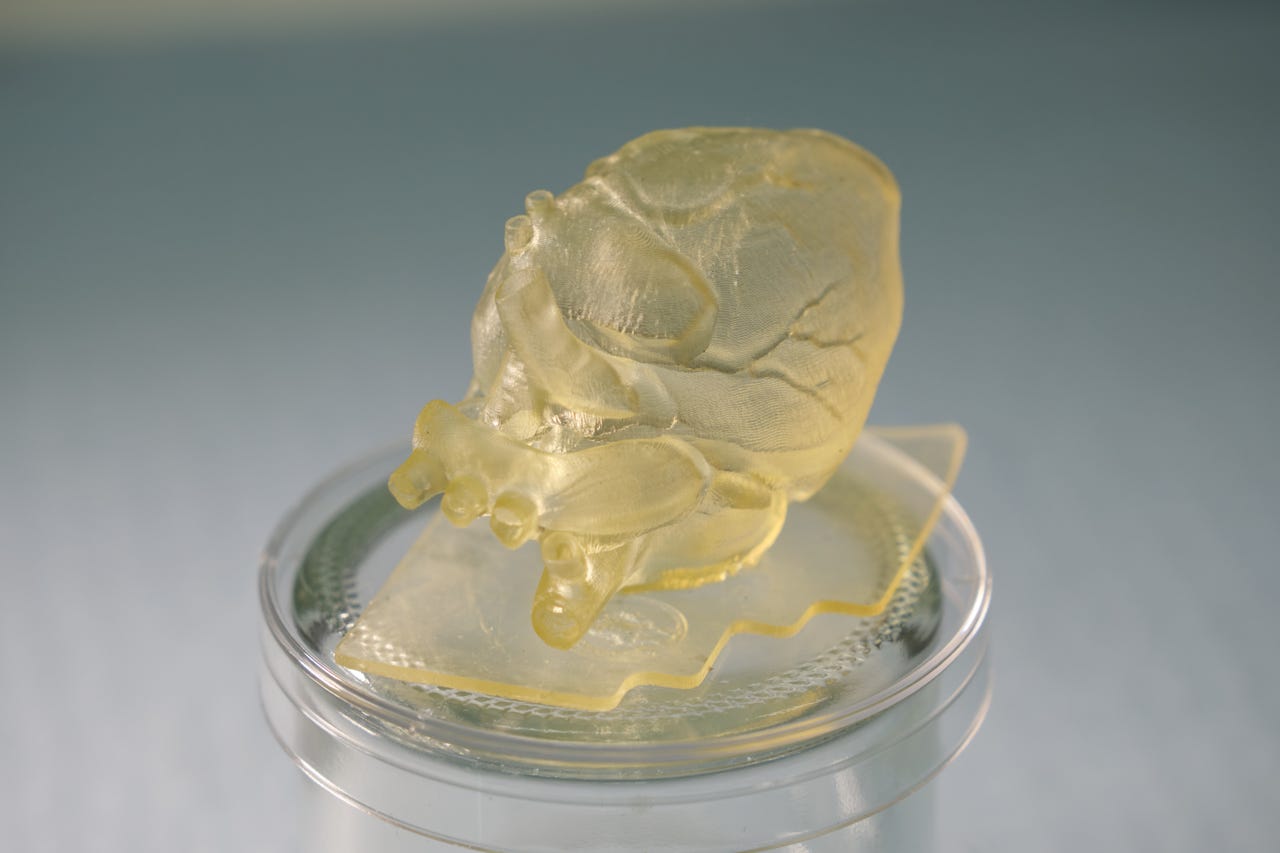

CSIRO develops silicone resins suitable for 3D printing medical parts

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) has developed silicone resins suitable for 3D printing medical parts.

The resins, according to CSIRO, are non-cytotoxic, highly transparent, feature tunable mechanical properties, and capable of printing complex designs in high resolution, including irregular shapes, thin walls, and hollow structures.

The motivation for developing the new technology, CSIRO polymer chemist Dr Ke Du said, was to help overcome challenges that exist when current silicon resins are used for 3D printing. These include low resolution, slow speed, and the need to use specialised printers, which can be costly.

"Our unique biocompatible resins boast a suite of excellent attributes," she said. "What's more, they can be used with off-the-shelf printers, without the need for modification."

The silicone resins can be used with a digital light processing (DLP) 3D printer with a light wavelength range of 360-500 nanometres, as well as a common commercially available desktop DLP 3D printers, CSIRO said.

The research team added the technology is also likely to work in stereolithography 3D printers and in other photocurable 3D printers, such as inkjet and extrusion.

CSIRO's biomedical polymer chemistry group team leader Dr Tim Hughes said the resins have the potential to be used in 3D printed medical devices such as dental devices, hearing aids, cochlear implants and prosthetics.

"We believe the resins may even help fast track prototyping some of these biomedical devices," he said.

The research team also discovered a novel feature of the resin is its superglue properties, which can easily affix glass and metal.

The team is now seeking industrial partners to help commercialise the patented product.

On Wednesday, CSIRO and Optus also released findings from research that looked at ways how bushfire resiliency of telecommunications infrastructure can be improved.

Specifically, the research used information on topography, fuel load vegetation type, and local bushfire weather severity to develop maps to assess where there is risk of damage to the network and where upgrades could reduce vulnerability to future bushfire events. Some of the threat factors that were considered included embers, radiation, and flame on and around Optus' sites with telecommunications equipment.

"Optus continuously aims to improve our network's resilience as we know communities rely heavily on our services, especially during natural disasters and extreme weather events," Optus managing director of networks Lambo Kanagaratnam said.

"Our collaboration with CSIRO has provided us with the analysis to allow us to target the best ways to protect the network where it could be most vulnerable."

Off the back of the study, Optus has used the findings to implement the recommended mitigations at two of its sites in Victoria -- Seville East and Dixons Creek -- that will be used by the company to build a longer-term bushfire resiliency program, which will also include in-house training to improve employees' awareness of bushfire threats and how to prepare for them.

"CSIRO has provided Optus with science and technology-based solutions that address a major threat facing all industries which rely on critical infrastructure: bushfires," CSIRO bushfire adaption research leader Justin Leonard said.

"The research can inform resiliency decisions across a number of industries, including telecommunications, energy, and emergency services."