The end of the supply chain as we know it?

There are two broad technology categories that are benefiting overwhelmingly from the upheaval caused by the global coronavirus pandemic: tools for working at home and technologies that help localize previously distributed supply chains.

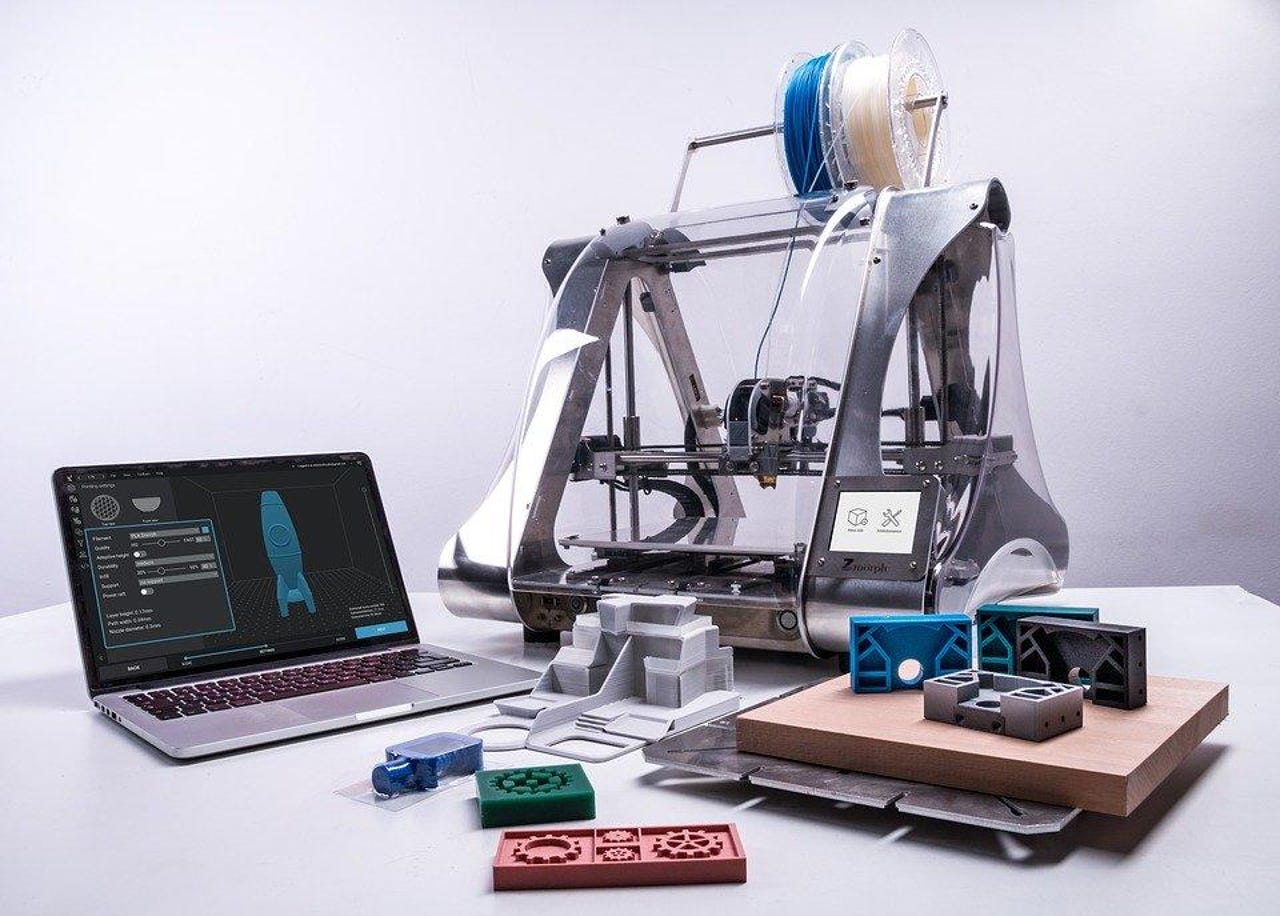

On that second count, this is a real moment for 3D printing. China's economic upheaval on the heels of the coronavirus, coupled with global closures of non-essential businesses, have upended supply chains across a vast number of sectors. But 3D printing, which has been gaining a larger footprint in traditional manufacturing thanks to the flexibility it affords, has allowed a savvy subset of manufacturers to stay afloat and even thrive over the past few months.

Every year a company called Sculpteo, a specialist in cloud-based online 3D printing and digital manufacturing, releases a State of 3D Printing market report. The 2020 edition is forthcoming (here's 2019), but in advance of release I had a chance to speak with Sculteo CEO Clément Moreau about the state of 3D printing and what's in store as we all grapple with a new reality.

One takeaway, which you'll see below? No industries have been unaffected by COVID-19, but some savvy companies are figuring out how to adapt with more nimbleness, savvy, and innovative thinking than others. Those are the ones that will survive.

Many thanks to Clément for his insights.

GN: What are some examples of ways 3D printing has been taking up the slack during COVID-19 related supply chain disruptions?

Clément Moreau: COVID-19 struck all industries, from factory closures to transportation clutters and a worldwide shortage of vital protective gear and medical equipment. 3D printing industry is no exception, we all live a very challenging situation. At the same time 3D printing has provided many answers during the pandemic. Sculpteo is a 3d printing factory, producing short run (1 to 10000 parts) production batches for its customers' needs. We have ensured the continuity of the production. And as a matter of fact, we have received orders from existing clients and several new clients searching for a way to keep on producing.

Thus, the speed and the flexibility offered by these technologies helped all frontline workers, and especially the healthcare workers, to face the lack of masks, protections, and equipment. A good example is the replacement valves for reanimation devices which were recreated in many hospitals through the world. We even printed small adaptors to connect existing scuba diving masks to medical respirators… Who could have planned this? Versatile, the technique offers the possibility to manufacture adapted parts faster and cheaper than traditional manufacturing techniques. 3D printing brought manufacturing closer to customers, which is critical in such a crisis! It saved lives!

GN: How has the pandemic and associated manufacturing challenges affected attitudes toward 3D printing in various sectors? Who are the big recent adopters right now?

Clément Moreau: 3D printing is changing the manufacturing process. The pandemic has broken a lot of myths around 3D printing. For instance, companies now realize that 3d printing might be less expensive than traditional manufacturing techniques such as plastic injection molding in a lot of cases. Another myth saw 3D printing as a hobby or a way to create "fake products"; industries now realize that it is, on the contrary, a real and reliable technique to develop, prototype and produce your end-use parts in numbers. It opens the world to infinite possibilities!

GN: What kinds of 3D printing technologies are proving most beneficial during the pandemic? What advances in recent years have come together to make 3D printing ready to face this unexpected wave of manufacturing challenges?

Clément Moreau: All 3d printing technologies found their ways through the crisis, with different purposes. The easiest and cheapest one, Fused Deposition Modelling, is the winner for relatively low-tech applications like face shields and masks, where Selective Laser Sintering or Stereolithography are used for more challenging applications, like PCR test probes for example.

GN: How do you see COVID-19 changing the short- and mid-term outlook for 3D printing? For instance, will adoption happen faster across a wider variety of sectors than otherwise might have been the case? Will there be accelerations in development? Investment?

Clément Moreau: 3D printing is finding its place as it helps to free industries from the "hostage situation" of traditional supply chains. When the dust settles, we are certain the trend will maintain! This shift which places 3D printing as a full manufacturing technique comes with an increase in investments.

In our State of 3D Printing survey, we interviewed thousands of 3d printing users to understand the trends of the market. Year after year, the survey shows that they double their investment. But players will also have to innovate quicker, in technologies as well as materials. Educating traditional designers to think beyond design for conventional manufacturing will also accelerate 3D printing.