What's hampering hardware development?

There's a lot going for hardware developers right now.

Rapid manufacturing, falling sensor prices, crowdfunding, and the growing availability of direct-to-consumer marketplaces have all abetted a new generation of hardware startups that would have stood little chance of getting off the ground even a decade ago.

Also: How distributed and agile manufacturing power new business models

Featured

Still, a full 71 percent of product teams depend on external manufacturing to bring their hardware into the real world. It turns out old paradigms and lingering supply chain inefficiencies may be constraining hardware development in a big way.

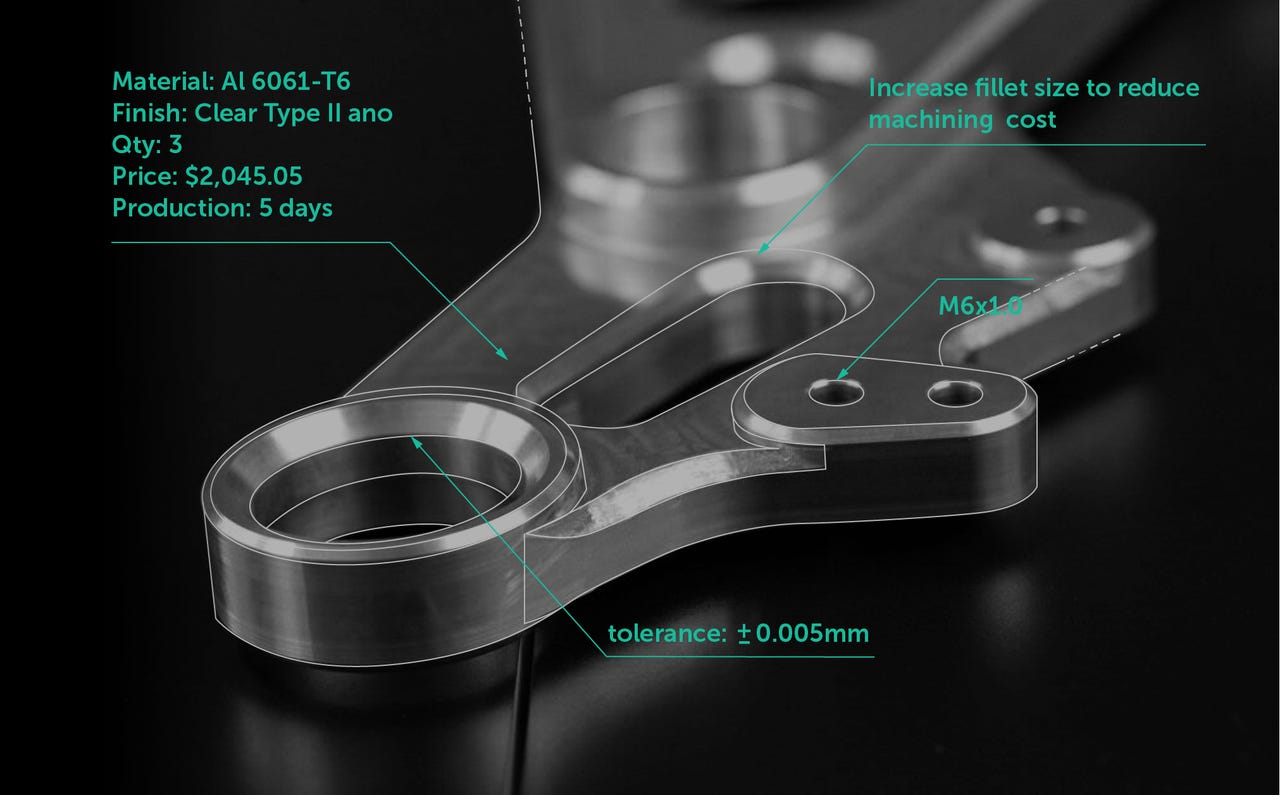

Those are the findings of a new survey on the state of hardware innovation by Fictiv, a manufacturing platform that connects developers to manufacturers with excess capacity.

Fictiv clearly has a stake in demonstrating that hardware development is inefficient and overly costly, but the results of the survey of more than 1,100 developers and manufacturers across dozens of industries are in line with complaints I've heard from young startups that have sprouted out of electrical engineering and robotics grad labs.

Among the shortcomings with the current paradigm, one of the most overlooked but obvious is that manufacturing still runs on email.

"While most software development teams have moved beyond email-based communication systems to save time and improve efficiencies," according to a Fictiv spokesperson, "93 percent of product developers and 94 percent of manufacturers rely heavily on email, followed by phone, to discuss part designs and manufacturability."

Because text-based, non-technical communication is necessarily full of ambiguities, that setup leads to a lot of misunderstandings and wasted time and effort in the development and manufacturing process.

Another problem is that small manufacturers that have managed to stay in business generally have very little capacity.

"Although hardware teams rely on external shops to help them move quickly, shops are time and resource constrained."

TechRepublic: Digital transformation in manufacturing is coming: Here's how IT departments can adapt

The Fictiv survey found that 75 percent of manufacturing personnel perform three or more roles in their organization. That makes it unlikely that they're working quickly enough to satisfy the rapid pace of hardware development in fields like robotics and mobility.

There's also a communications gap when it comes to how knowledgeable engineers and manufacturers are abut the manufacturing process.

"The survey revealed a wide gap in perceived manufacturing knowledge between engineers and manufacturers, as well as infrequent manufacturability feedback and common miscommunications with 66 percent of developers reporting a miscommunication with a CNC machining or 3D printing shop in regard to design intent on a part and 74 percent of manufacturers reporting a similar miscommunication."

For more detailed information on inefficiencies in the current manufacturing paradigm, check out the full survey results from Fictiv.