CSIRO develops electronics-grade graphene from soybeans

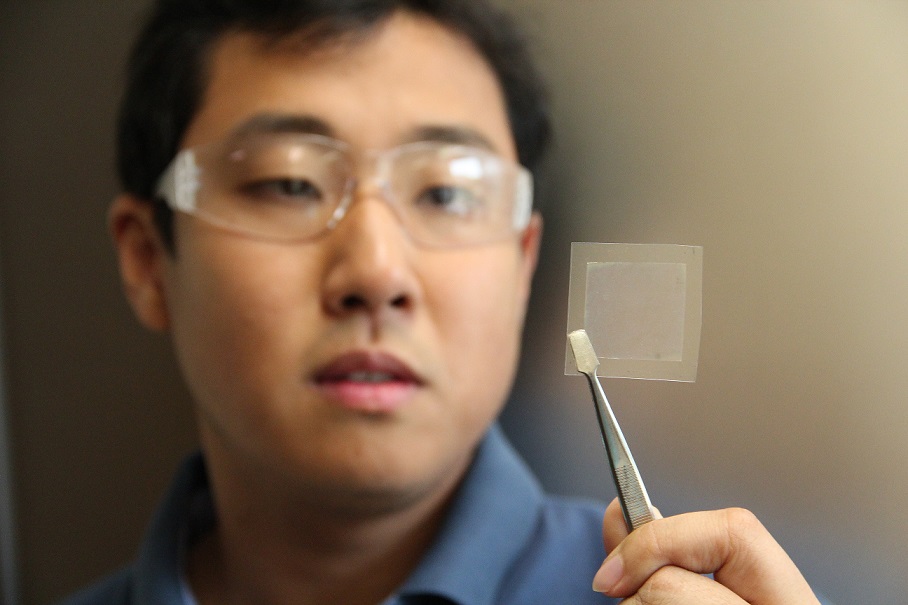

CSIRO scientist Dr Dong Han Seo holding a piece of graphene film

A team of scientists from the Commonwealth Scientific and Industrial Research Organisation (CSIRO) has potentially removed a major roadblock in commercial graphene production, developing a low-cost soybean-based graphene material that can be used by electronics manufacturers.

In conjunction with researchers from The University of Sydney, University of Technology Sydney, and The Queensland University of Technology, CSIRO developed the novel "GraphAir" technology, which it said eliminates the need for a highly-controlled environment. Essentially, the technology grows graphene film in ambient air with a natural precursor, making its production faster and simpler.

Previously, graphene was purely grown in a highly-controlled environment with explosive compressed gases, requiring long hours of operation at high temperatures and extensive vacuum processing.

"This ambient-air process for graphene fabrication is fast, simple, safe, potentially scalable, and integration-friendly," CSIRO scientist Dr Zhao Jun Han said. "Our unique technology is expected to reduce the cost of graphene production and improve the uptake in new applications."

Graphene is a carbon material that is one atom thick. Its thin composition and high conductivity lends itself to a range of applications such as miniaturised electronics and biomedical devices.

Its properties enable thinner wire connections, which the CSIRO said provides extensive benefits for the likes of computers, solar panels, and sensors. It may also see the batteries in smartphones last 25 percent longer.

According to the CSIRO, GraphAir transforms soybean oil into graphene films in one single step. Using heat, soybean oil breaks down into a range of carbon building units that are essential for the synthesis of graphene, the CSIRO explained.

"Our GraphAir technology results in good and transformable graphene properties, comparable to graphene made by conventional methods," CSIRO scientist Dr Dong Han Seo said.

In addition, the CSIRO team also transformed other types of renewable and waste oil, such as those leftover from barbecues or cooking, into graphene films, allowing its application beyond electronics and to techniques used for water filtration and purification, renewable energy, sensors, and medicine.

Researchers at MIT in the United States discovered last year that graphene could be used to slow light down below the speed of electrons to create an intense beam of light, paving the way for light-based circuits in ultra-compact computing devices.

The research team explained that using light instead of flowing electrons to move and store data could push operating speeds up to vastly higher levels than those achieved by today's chips.

Although still theoretical, the discovery increases graphene's potential in computing chips. Scientists at IBM Research have been exploring how graphene can be used to create new chips that exploit the way electrons move faster through graphene than through other semiconductor materials.

The CSIRO is now on the hunt for an industry partner to develop new use cases for graphene.