Engineering the 10 TB notebook drive

We all take it for granted that disk capacities keep rising, but did you ever wonder why?

Disks are way more complex than you know Chips have a lot of brilliant technology, but disk drives are just as complex. For example, current disks use 50 nanometer (nm) track sizes, equivalent to the 45 nm feature sizes in the very latest chips. And they read and write those tracks while spinning 120 times a second at a 10 nm flying height!

To illustrate this I'm going to focus on a presentation at DISKCON 2007 by longtime Toshiba researcher Dr. Hiroyuki Hieda.

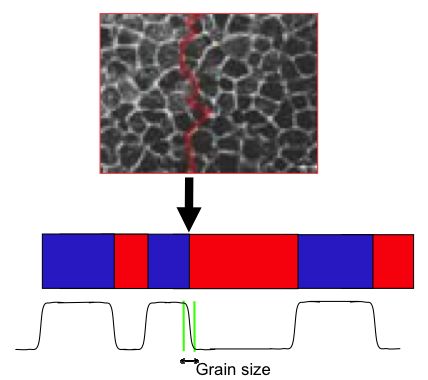

200 Gbit/in2 now Disk platter size is a constant, so drive vendors have to get more bits per square inch. Currently disks are at about 200 Gbit/in2, close to the grain size of the plated metal.

When the grain is the same size as the track, the track starts to bounce around quite a bit, making it difficult to read and write the data.

10 Tbit/in.2 then Current technology takes drives to the 1 Tbit/in.2 range, or a 1 TB 2.5" drive. Then where do we get the next 10x of drive density?

There are 2 good candidates, HAMR and BPM.

HAMR, BPM or both? Most of the DISKCON engineers agreed that HAMR - Heat Assisted Magnetic Recording - is the leading candidate. HAMR uses a laser to heat the recording media before writing. The makes the spot easier to magnetize and, when cool, makes the data much more stable.

Bit patterned media The other leading contender is BPM - Bit Patterned Media. The dots magnetize as a group so they are more stable and they can be tightly packed for density. Here's a picture of a kind of BPM:

This BPM sample is only 300,000,000,000 bits/in2, far short of the goal. Research into the self-assembly - i.e. the spontaneous organization into ordered structures - of polymers has shown that nice regular patterns of the requisite density can be created, but then there is one more problem: how do you get the patterns to line up in circular tracks?

Combine HAMR, BPM and electron-beam lithography HAMR offers magnetic stability at very small feature sizes. BPM provides the tiny features. How do you get them lined up?

E-beam lithography. Often hailed as the next step in chip manufacturing, but avoided because of cost and complexity, e-beams enable much smaller feature sizes than visible or deep ultraviolet light. The problem for chip vendors is that e-beams are highly focused and slow to scan across a chip's mask. Light is much faster.

E-beams are viable for disks though. The e-beam creates a master that stamps out millions of disk platters with nano-scale features. That's how CDs and DVDs are manufactured today, except for the e-beam feature sizes.

Prototype self-assembled BPM + e-beamed groove If current thinking holds, the 10 TB notebook drive will be built using HAMR and self-assembled BPM on disk platters stamped out by e-beamed masters. Here's what a laboratory prototype looks like, up close and personal:

The Storage Bits take Disk capacities double about every 2 years, so the 10 TB 2.5" drive is about 10 years away. While I've focused on the problems of the physical media, disk storage researchers are banging away on a dozen major research areas - including signal processing, servos and heads - to make higher capacity storage possible.

I'd like to see the disk vendors do a better job of communicating the incredible work they are doing. Storage is the hardest part of modern computing, disk vendors are doing the heavy lifting, and they get very little credit for all their hard work.

That is just wrong. Disk technology is even more amazing than chip technology, but the engineering-driven disk companies are wallflowers at the big technology dance.

Comments welcome, as always.