Meet the 3D-printed robots with soft skins

MIT CSAIL researchers have developed a new way to 3D-print robots which make the devices less prone to damage -- by giving them soft skins.

These days, robots are used in many critical areas -- working for the military, used in surveillance and land surveys, and are the prized possessions of hobbyists, among others.

The delicate balance of components within a robot can be damaged after drops, crashes, or collisions as it usually has no decent layers of protection or padding. However, a team of engineers and scientists hope to improve future robotics -- through soft materials.

Researchers at the MIT Computer Science and Artificial Intelligence Laboratory (MIT CSAIL) said the team's "Programmable Viscoelastic Material" (PVM) makes robots "safer, more resilient and more precise in their movements."

"It's hard to customize soft objects using existing fabrication methods since you need to do injection molding or some other industrial process," says Hod Lipton, professor of engineering at Columbia. "3D printing opens up more possibilities and lets us ask the question, 'can we make things we couldn't make before?'"

The technique can be used to program 3D-printed robotics and materials to precise levels of stiffness and elasticity, depending on what the device will be used for.

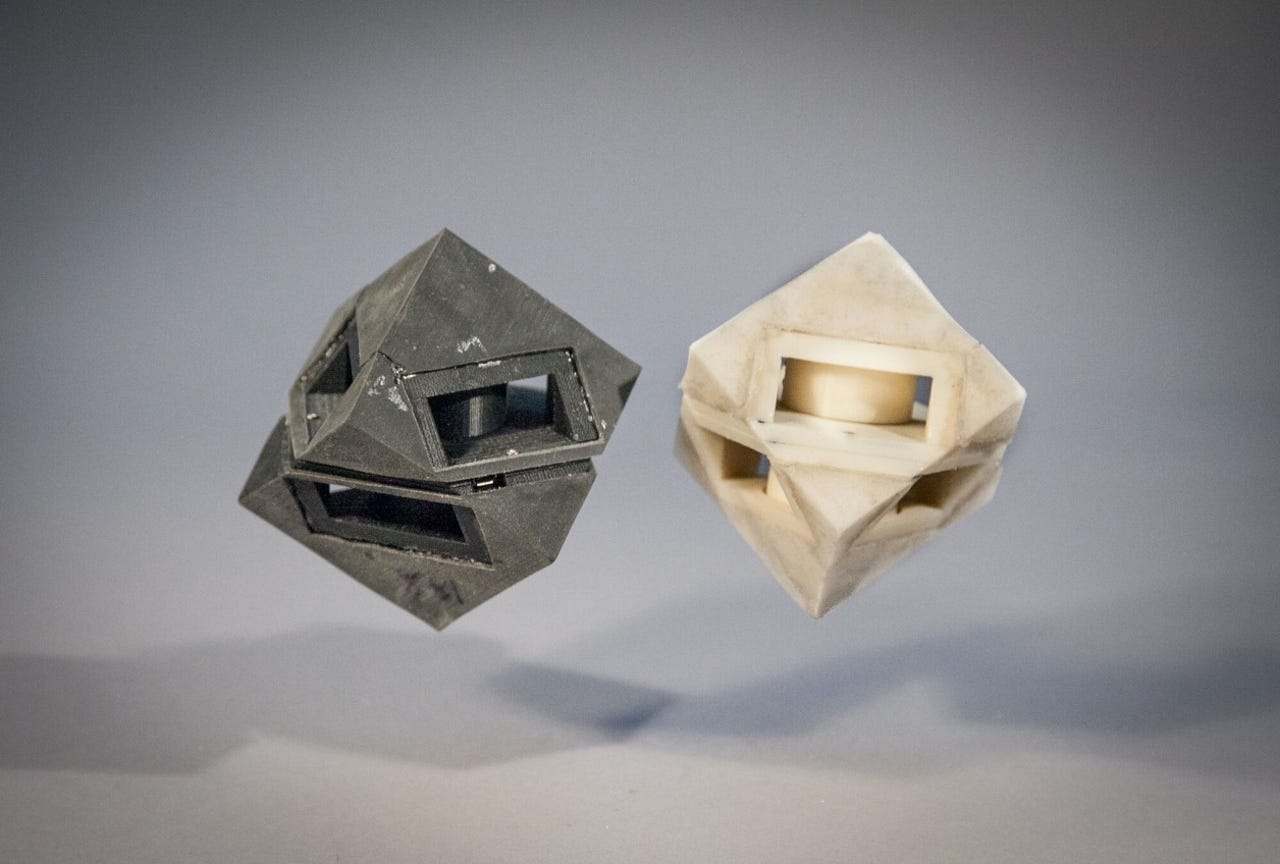

The team 3D-printed a cube robot which moves by bouncing. They used a rubber-like material called TangoBlack+ to print both the cube and protective skins. The printed shock-absorbing "skins" were able to reduce energy impact levels by 250 percent, improving the durability of the robot.

"That reduction makes all the difference for preventing a rotor from breaking off of a drone or a sensor from cracking when it hits the floor," says CSAIL director Daniela Rus, who oversaw the project. "These materials allow us to 3D print robots with visco-elastic properties that can be inputted by the user at print-time as part of the fabrication process."

The technique can also be used for other devices, such as drones, mobile phones, shoes, and helmets. The MIT CSAIL researchers say that drone developers, in particular, could use the technique to create shock-absorbing legs on delivery drones, which would extend the life of the unmanned aerial vehicles (UAVs) by keeping them free from damage for longer. More durable, longer lasting drones could be of interest to companies like Amazon and Google which are developing drone delivery services for the consumer market.

See also: FAA issues drone regulations, but drone delivery services await more rules

The research, supported by a grant from the National Science Foundation, will be presented at next week's IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) in Korea.