Rethink Robotics rethinks its software

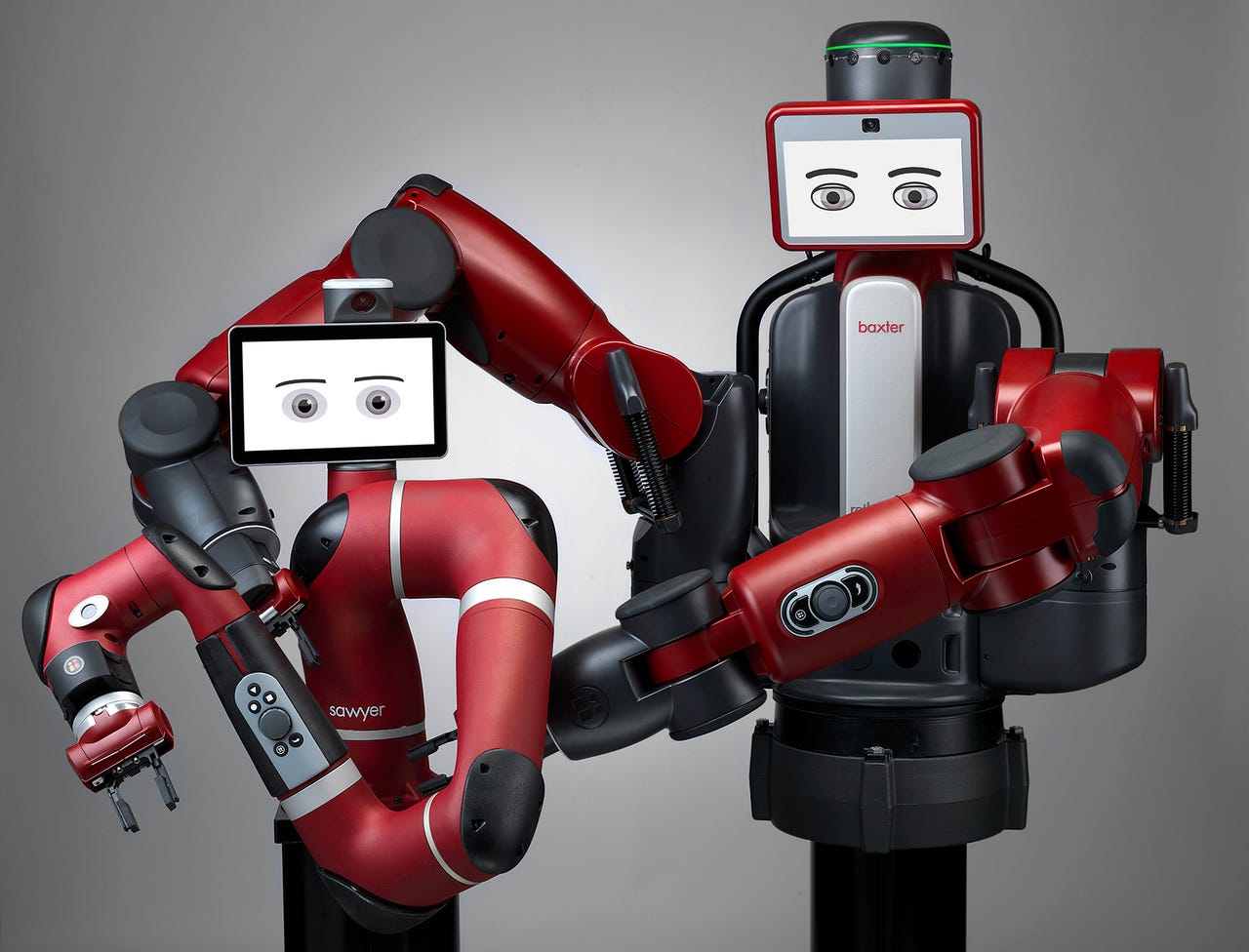

Baxter and Sawyer will now operate with Intera 5. (Image: Rethink Robotics.)

Today's industrial robots can be programmed to do complicated tasks involving multiple steps. The only problem is that most warehouse employees don't know how to program robots, and roboticists are awfully expensive. Rethink Robotics has announced a new software release that should make it much easier to put robots to work.

The Boston-based firm is already known for making "easy" robots; Sawyer and its predecessor Baxter are collaborative robots that can learn by demonstration. Existing employees can train a robot by simply grabbing its arm and showing it what to do. This technique has worked well for simple tasks, but more complicated jobs have required specialized programming.

Now, the robots will run on Intera 5, a software platform that the Rethink Robotics team says will allow manufacturers to integrate robots into factories in just a few hours. This kind of fast and easy deployment will be a key factor in the widespread adoption of industrial robots. Despite the obvious benefits of automation -- consistently high throughput with minimal labor -- the idea of adding a fleet of robots to a traditional warehouse can be overwhelming.

In an announcement about the software release Rethink Robotics President and CEO Scott Eckert said:

With the introduction of Intera 5, we've created the world's first smart robot that can orchestrate the entire work cell, removing areas of friction and opening up new and affordable automation possibilities for manufacturers around the world. Intera 5 is driving immediate value while helping customers work toward a smart factory, and providing a gateway to successful industrial internet of things (IIoT) for the first time.

We wouldn't usually make such a fuss over a simple software upgrade, but Intera 5 is a complete overhaul. IEEE Spectrum reports that the new version is based on ROS (Robot Operating System) and it is the result of 30 people working on the new code for the last two years. The software platform has a behavior tree that is presented as a visual diagram. Operators can still grab the robot's arm to show it what to do, but now they can also zoom in on the behavior tree to program complex tasks based on a string of specific actions.

If industrial robots can truly be integrated in just a few hours, it will make them more appealing on several levels. First, it eliminates the fear that they are complicated machines that require robotics expertise. Second, the quick setup also helps avoid interrupting normal operations, which reduces the initial cost. Additionally, the robots are now flexible enough for applications that experience frequent unpredictable fluctuations in demand, such as making clothes for the fashion industry.

Video: Trump may bring jobs back to the US, but robots will get them