Robot spending spree: Automation systems are flying off the shelves

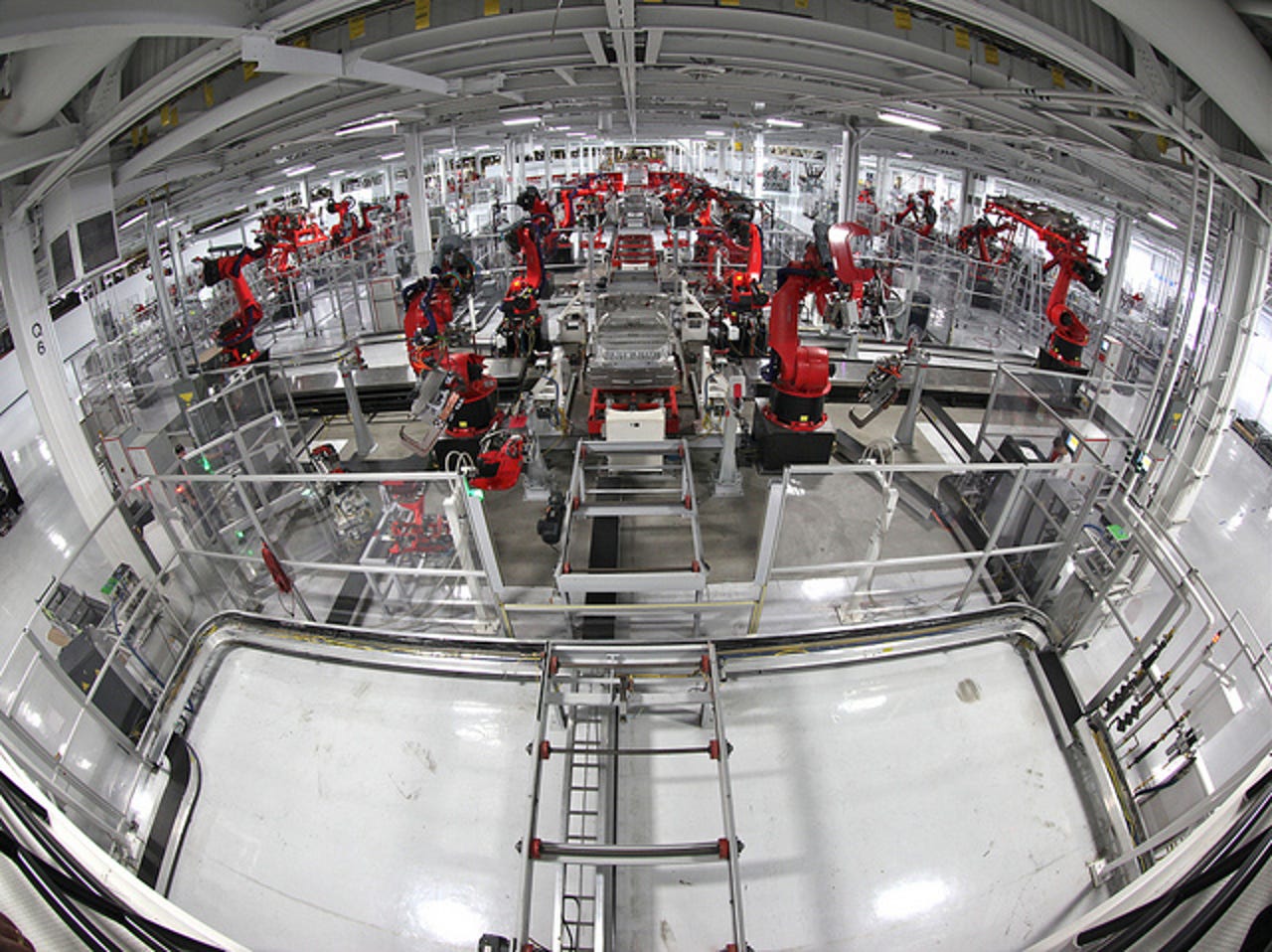

The number of robots ordered by automotive OEMs and component suppliers increased 16 percent and 4 percent, respectively, to begin the year. (Image: Tesla)

The robots indeed are coming -- and in record numbers. As organizations find new ways to adopt greater automation into their processes, the machines that support these efforts are flying off the shelves.

The North American automation industry set new records to begin 2016, according to the Association for Advancing Automation (A3), the industry's trade group. The advent of more automation in manufacturing promises increased efficiencies in production and the ability to compete globally, the group said. A3 tracks the robotics, machine vision, and motion control markets for its three associations.

North American companies ordered a total of 14,583 robots valued at about $817 million during the first half of 2016, A3 said in a report released in August 2016. The number of units ordered in the period marks a new record, growing 2 percent over the same period of 2015, which held the previous record.

The number of robots ordered by automotive OEMs and component suppliers increased 16 percent and 4 percent, respectively, to begin the year, and was the largest driver of the market's record performance, the organization said.

Likewise, the use of robots in the food and consumer goods industry soared in the first half of the year, with companies ordering 41 percent more robots than the same period of 2015. Total orders by all other non-automotive industries actually decreased by 14 percent.

In terms of robotics applications, the biggest increases were seen in inspection (69 percent), assembly (38 percent), and spot welding (21 percent). The Robotic Industries Association (RIA), one of the organizations owned by A3, estimates that some 265,000 robots are now at use in North American factories, third highest following Japan and China.

The increasing functionality, flexibility, affordability, and safety of robots is contributing to how the dynamic market is reshaping the global manufacturing landscape, said Jeff Burnstein, president of A3.

Other areas of automation also showed growth in the first half of the year. For example, global shipments of motion control products grew by 3 percent to $1.54 billion. This was largely driven by growth in three key product categories -- actuators/mechanical systems, electronic drives, and motion controllers -- according to Motion Control and Motor Association (MCMA), another unit of A3.

And the machine vision market began in 2016 on the heels of two consecutive record-setting years for sales in North America. In spite of a 7 percent "cyclical contraction" in the first half of the year to $1.1 billion, largely tied to the stagnation in the semiconductor industry, the machine vision market in North America remains a key growth segment within the automation landscape, A3 said.

The group describes these systems as the "eyes" of emerging smart factories and robotic systems, critical to the success of next-generation automation systems. Products including smart cameras, which are vision systems contained within the same camera enclosure, are creating new applications for manufacturers. In North America, the smart camera category increased 4 percent year over year to $157 million in the first half of 2016.

Machine vision systems (which includes smart cameras and application-specific machine vision systems) rose 7 percent in the second quarter to $495 million, compared with the first quarter of 2016.