Formnext 2019: 3D metal printing, industry use cases, adoption accelerate

Featured

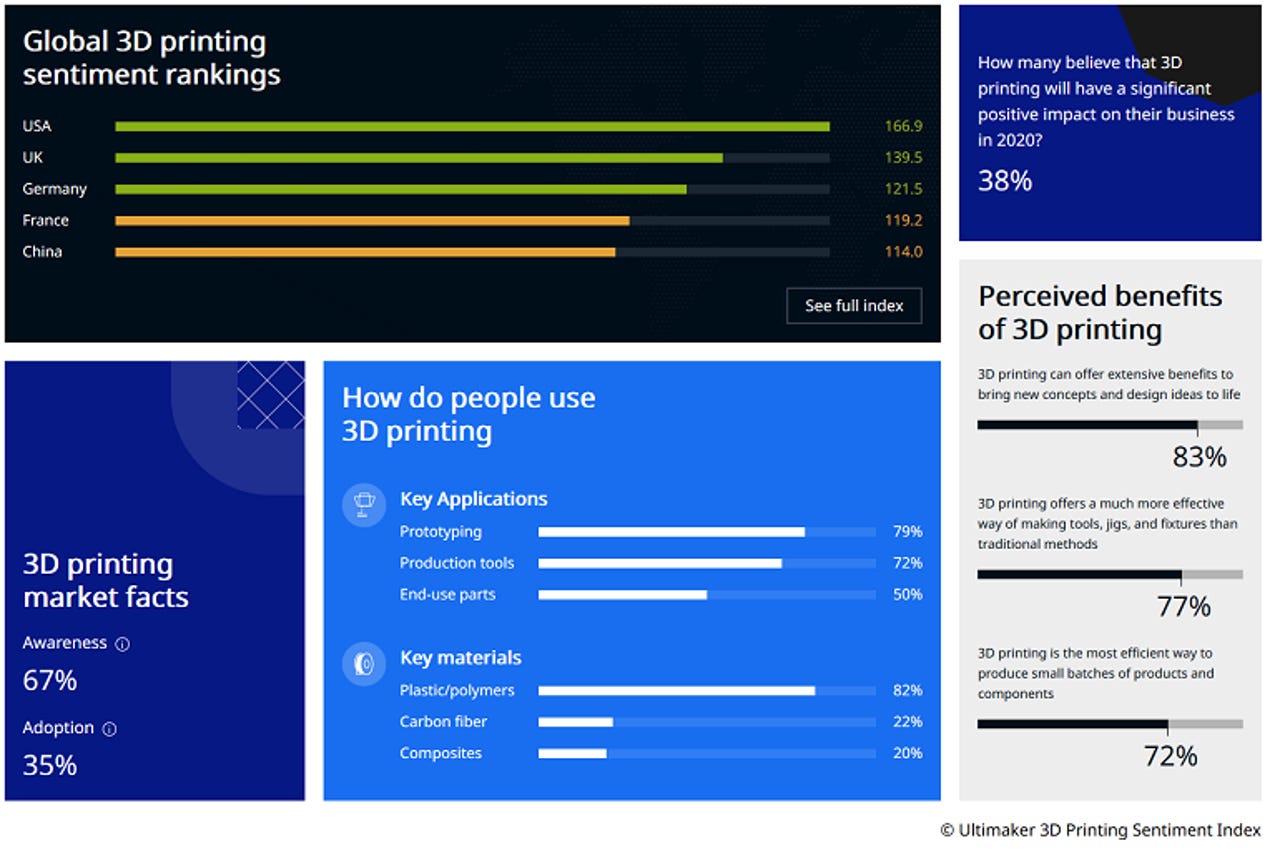

Additive manufacturing is taking center stage for production parts as well as prototyping with awareness being led by the Netherlands, Switzerland, and the US, according to an Ultimaker survey.

Ultimaker surveyed more than 2,500 3D printing pros to gauge adoption and use cases by industry. Key findings include:

- US market awareness for 3D printing checked in at 77%, but adoption was at 34%.

- China had the highest rate of 3D printing adoption at 53% followed by France at 42%.

- 77% of US respondents use 3D printing to make prototypes.

Here's the roundup from Formnext:

Additive manufacturing in the rail industry via Stratasys

Stratasys launched a parts and digital inventory system for the rail industry. The Stratasys Rail Industry Solution is designed to keep passenger trains, including long-haul and urban metros, to utilize 3D printed parts and bolster uptime. The system includes the Stratasys Fortus 3D printers and materials such as its ULTEM 9085 resin and Antero 800NA material.

Also: Everything you need to know about 3D printing and its impact on your business

According to the company, materials in the Rail Industry Solution have passed the European Union's Rail Standard, EN 45545-2.

The company said it has a series of customers and partners using Rail Industry Solution including Angel Trains, Bombardier Transportation, Chiltern Railways, DB ESG, and Siemens Mobility. With the systems rail operators can produce parts within a day or two regardless of the age or uniqueness of the train.

3D Systems goes vertical

3D Systems outlined a series of production systems for healthcare, aerospace and automotive use cases. CEO Vyomesh Joshi said the 3D systems will hit the 200 million parts mark on its system. 3D Systems highlighted the following:

An automotive production system designed to manufacture parts such as an in-door bracket and washer fitting to speed up development. the automotive stack includes Geomagic Design X, 3D Sprint, ProJet MJP 2500, ProX SLS 6100 and 3D Connect among others.

- Aerospace as a joint production and workflow system with partner GF Machining.

- Healthcare use cases for anatomical models, surgical planning and implants.

- 3D Systems also launched a series of new materials for industry use cases.

Markforged launches turbo mode

Markforged, which makes metal and carbon fiber 3D printers, said its X7 3D printer is getting Turbo Print, a feature that doubles print speed without sacrificing quality. Turbo Print will be released Dec. 16 and is compatible with second-generation X7 3D printers, which have been shipping since June.

Metal takes center stage

3D metal printing was a big theme at Formnext. Here's the breakdown:

- Desktop Metal launched Shop System, a metal binder jetting system designed for machine shops and metal job shops. The system starts at $150,000. Shop System will complement Desktop Metal's Studio System, a low volume prototyping system.

- ExOne debuted a production model of its X1 25PRO metal 3D printer. The X1 25PRO can print more than six metal materials that have passed ExOne's qualification process. The system can also print a variety of other beta materials on track for qualification.