Stratasys launches carbon fiber material, aims for wider adoption

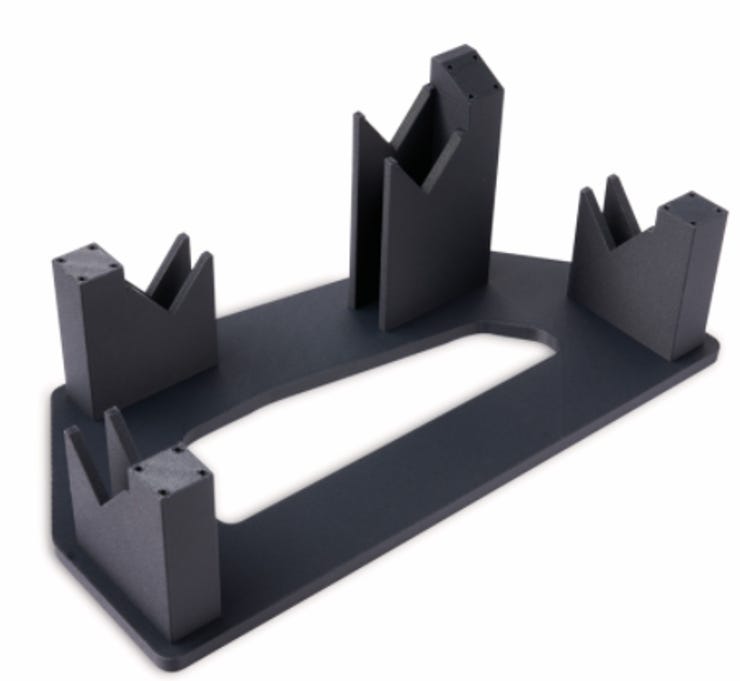

Stratasys part made with FDM ABS-CF10 material.

Stratasys said it is launching carbon fiber material for its F123 Series 3D for the first time.

Carbon fiber materials have been previously reserved for the industrial-strength Stratasys FDM 3D printers for the manufacturing of jibs, fixtures and tooling.

By bringing carbon fiber to the F123 Series printers, via FDM ABS-CF10 material, Stratasys will bring the material to more end users of the F170, F270 and F370 3D printers.

ABS is an acronym for Acrylonitrile Butadiene Styrene, a popular thermoplastic for 3D printing. ABS is known for being sturdy, able to handle high heat and resist wear at a low costs. Stratasys recently acquired Origin for $100 million to bolster its materials ecosystem.

According to Stratasys, carbon fiber material is an alternative to metal parts. FDM ABS-CF10 includes 10% chopped carbon fiber, has 15% more strength than standard ABS and is lighter than metal. Stratasys estimates that the additive manufacturing market for polymer jibs and fixtures is expected to be almost a $600 million market by 2023.

The material will be available April 2021.

Material innovations are among the ways that additive manufacturing will scale.

More:

- Desktop Metal CEO Ric Fulop on additive manufacturing, SPACs, innovation

- Formlabs launches new Fuse 1 industrial 3D printer

- How to learn Fusion 360: From makers, for makers

- How 3D printing is helping CERN scientists upgrade the world's largest machine

- How the 3D printing industry is stepping up to help the COVID-19 response

- Stratasys launches J826 mid-range 3D printer

- How Stratasys is using 3D printing to help combat COVID-19