Stratasys partners with Siemens, Ford, Boeing

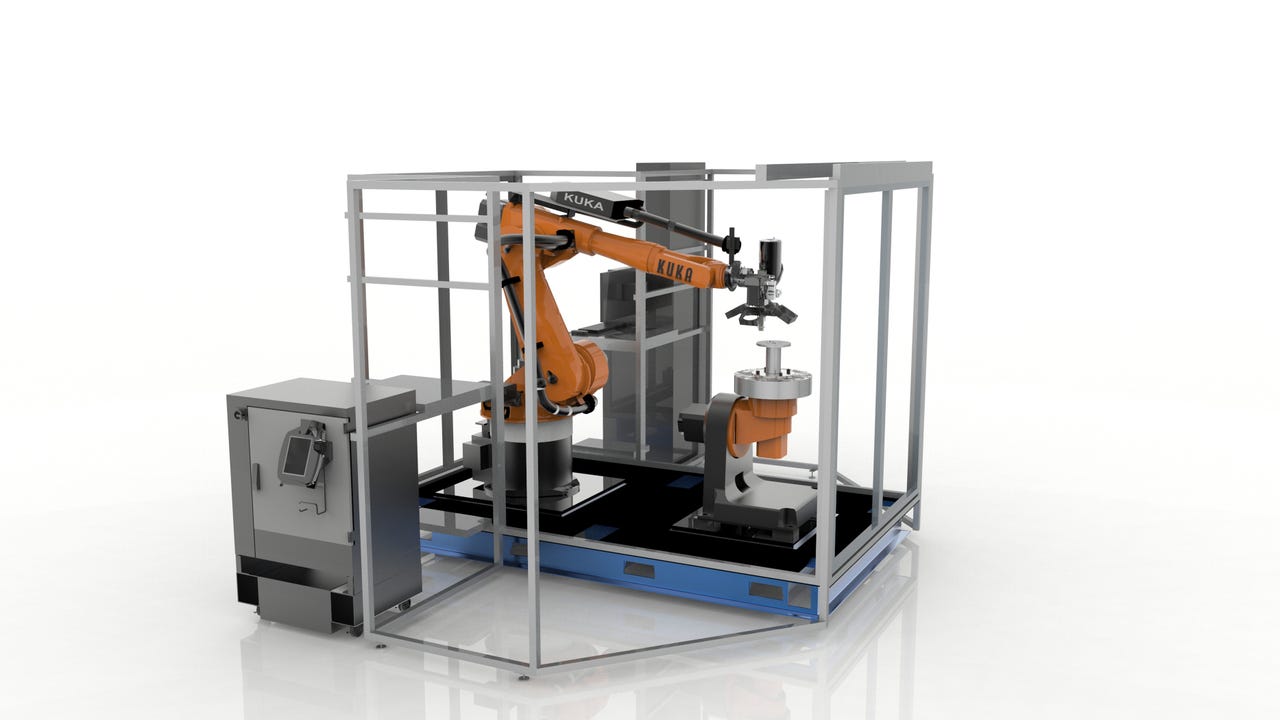

Stratasys' new Robotic Composite 3D Demonstrator gives manufacturers greater ability to make high-value composite production parts.

Stratasys on Wednesday is unveiling new technologies in 3D printing, along with a series of major partnerships, all with the aim of advancing additive manufacturing for end-use parts.

The new 3D demonstrators that Stratasys is rolling out were co-developed with Boeing and Siemens, and have clear applications in the automotive and airplane industries. Ford is also partnering with Stratasys to explore applications for the new technologies.

"We're very excited to be building on decades of knowledge," said Rich Garrity, president of Stratasys Americas. "We understand the pain points that manufacturers are struggling with, whether that's trying to get better products to market faster, trying to differentiate the experience, or being able to improve performance."

Both new demonstrators expand Stratasys' Fused Deposition Modeling (FDM) technology across manufacturing, allowing for the production of bigger, stronger and higher quality parts: The Infinite-Build 3D Demonstrator focuses on producing large thermoplastic parts and tools, while the Robotic Composite 3D Demonstrator incorporates Siemens technology for the automated production of composite structures.

The Infinite-Build demonstrator is called that because, by flipping the vertical FDM process on its side, "we're able to to print parts in that vertical plane direction essentially as large as we want," Garrity explained.

It would effectively allow a manufacturer to build, for instance, an interior part of an aircraft all at once. It also allows for customization, such as personalizing those interiors for a specific airline. The Infinite-Build allows for speedier production of tools and parts -- at least 10 times faster than current production speeds, Garrity said. It also ensures accuracy and repeatability, giving manufacturers confidence they're building the products they designed. Its tool-changing capability gives manufacterers the ability to change materials on the fly.

Boeing, one of Stratasys' leading customers for several years, played a key role in defining the specifications for this demonstrator so it would meet their needs for the production of low-volume, customized, lightweight flight parts.

Applying additive manufacturing to end-use parts isn't totally new. Last year, Stratasys announced that Airbus was producing more than 1,000 flight parts using its high-end additive manufacturing 3D printers. However, the Infinite-Build is "is taking that to a whole new level," Garrity said.

While the potential applications obviously go beyond aerospace, the market there is significant: The aircraft interiors market is estimated to be worth $13.5 billion.

Meanwhile, Ford Motor Company is exploring automotive manufacturing applications for the Infinite-Build. After using additive manufacturing technology for nearly 30 years for prototyping, the automotive company is now exploring its more functional applications.

Using the Infinite-Build for larger products should eventually help in the production of durable, end-use products, according to Ellen Lee, Ford's technical Leader of additive manufacturing. Already it "is essential in the short-term," she said, for the production of tools and fixtures.

Ford is also interested in working with Stratasys in driving the materials space more toward automotive industry needs, Lee said.

Meanwhile, Stratasys' new Robotic Composite 3D Demonstrator should give manufacturers greater ability to make high-value composite production parts. Making composite parts is currently a labor-intensive process, but the Robotic Demonstrator uses an eight-axis motion system to precisely place materials in any number of directions.

Andreas Saar, vice president of manufacturing engineering solutions for Siemens PLM Software, said the demonstrator will "change the landscape of what's on the market today."

Siemens has been investing intensively for more than a year in additive manufacturing as both a consumer and supplier of technology, Saar said. Several companies have expressed interest to Siemens in bringing this equipment to the factory floor, he said.

"With our experience from Siemens' side in terms of driving robotics... and Stratasys' vast experience in materials and FDM, we believe this is a perfect combination to advance additive into a production environment," Saar said.