From rovers to snake bots, see how Pittsburgh does robotics

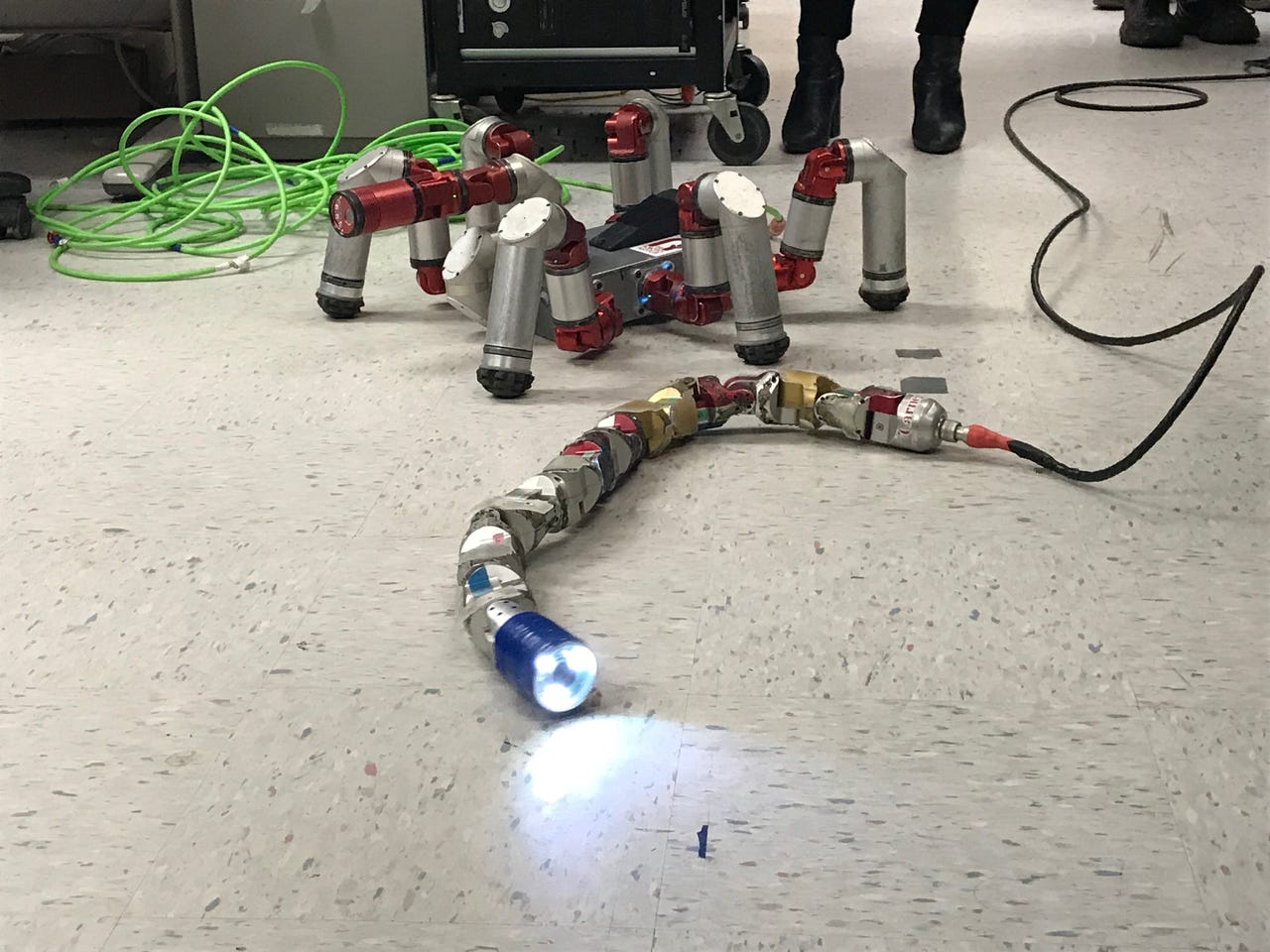

Howie Choset's snake robot

One of the famed snake robots from the team of Howie Choset, head of Carnegie Mellon University's Biorobotics Lab. Choset's snake robots have deployed all over the world to assist with disaster search and rescue, archaeological excavation, nuclear inspection, and even the development of minimally invasive surgery.

The snake-like design is key to the robot's effectiveness in disaster search-and-rescue. According to Choset, this particular form factor provides more motive force to wiggle through tight spaces than would be possible with legs, which could become detached or unstable.

Innovating the colonoscopy

A look inside the Biorobotics Lab at Carnegie Mellon University. Here, a student demonstrates how a shrunk down version of Howie Choset's snake robot is being applied to colonoscopy procedures. The aim is to use the snake robot's unique, modular design to perform minimally invasive colonoscopies.

Autonomous floor mopper

Developed by Carnegie Robotics, a spin out of Carnegie Mellon University's National Robotics Engineering Center (NREC), this is a fully autonomous floor scrubber that aims to make commercial floor cleaning in retail, hospitality, education, healthcare, and other industries more productive.

Duro receiver

Built by Carnegie Robotics in partnership with Swift Navigation, Duro is an enclosed multi-frequency RTK receiver that's meant for outdoor navigation applications in the areas of precision agriculture, military, infrastructure mapping, and industrial and maritime vehicles.

High-tech inspection

Carnegie Robotics worked with a provider of pipe and underground inspection equipment to develop this camera system that goes into sewers. The entirely bootstrapped Carnegie Robotics typically sells through a business-to-business relationship, partnering with other companies and helping to make their products autonomous through advanced robotic components.

Carnegie Robotics production lab

Carnegie Robotics produces advanced robotic sensors and field robotic technologies for the defense, agriculture, mining, infrastructure and energy industries, among others. Here's a look inside the company's production lab, where operators test final products before shipping.

Astrobotic HQ

A spin-out of CMU, Astrobotic is developing space robotics technology for planetary missions. The company wants to be a logistics service provider for businesses, nonprofits, and research institutions that want to ship payloads of up to 265 kilograms to the moon. Its core development is the Peregrine Lunar Lander, which is designed to perform an autonomous landing with a target accuracy of 100 meters.

The dawn of lunar logistics

John Thornton, CEO of Pittsburgh-based Astrobotic. Astrobotic is an official NASA partner via the Lunar CATALYST program. The company has 24 prior and ongoing NASA contracts, a commercial partnership with Airbus DS, a corporate sponsorship with DHL, 11 deals for its first mission to the moon and 130 customer payloads in the pipeline for upcoming missions.

The CubeRover

A spin-out of Astrobotic, the CubeRover is pitched as a low cost option for planetary exploration. Its modular design is meant to support the unique payload demands for each customer. Once deployed, the CubeRover is expected to be the smallest rover to traverse the lunar surface.

Bossa Nova's retail bots

Bossa Nova's shelf-scanning bots are being tested by 50 Walmart Supercenters. The main focus in on inventory optimization. The pitch is that these robots and the data they gather can help level the playing field between e-commerce and brick and mortar by providing data-optimized inventory tools.

Robotic arms inside Re2

Another CMU spin-out, RE2 (Robotics Engineering Excellence) makes human-like robotic arms for air, ground and sea applications. It also creates intuitive controllers and autonomy solutions for these arms.

Near Earth Autonomy

Near Earth Autonomy is building systems for autonomous flight. Its innovation enables a range of unmanned aircraft (i.e., sub-meter to full scale) to operate across multiple applications. The company works with customers to provide flight-proven core technologies to address inspection and mobility needs. Here, the company displays a concept drone with autopilot technology that could one day facilitate autonomous drone deliveries.

Seegrid's autonomous forklifts

Seegrid's focus is on the automation of material handling. Its self-driving forklifts are used to haul pallets in massive warehouse operations for companies such as Whirlpool, General Motors and Zulily.