Robots at Work: Meet the non-engineer who automated his small business

Robotics

Thanks to falling sensor prices, a robust and supportive maker community, and the convergence of technologies like rapid prototyping and powerful microprocessors, we're beginning to see the fruits of a powerful DIY robotics movement. Lunar rovers and satellites can now be made with off-the-shelf parts, and there are examples of enterprising small business owners creating or customizing their own automation solutions to increase productivity and save money.

One of these business owners, Curtis Lucas, has an impressive story of ingenuity and technological derring-do, which I asked him to share with ZDNet. It's a phenomenal example of how automation is creeping into small and mid-sized businesses, as well as how accessible automation technology is becoming, even to non-engineers.

Also: The SMB Guide to Industrial Automation

Lucas owns Alaska Professional Janitorial (APJ), a commercial janitorial business. Like many small businesses, APJ faces high labor costs and a tight labor market, a double whammy in an industry like janitorial services, where as much as 95 percent of cost goes to labor, according to Services, an industry trade publication.

After posting a job opening a couple years ago, APJ received 50 applicants. Of those, 40 didn't pass the initial screening. Out of the remaining ten, APJ narrowed the field to three candidates, but none accepted the job. Frustrated but undeterred, Lucas considered his options. Then he started thinking outside the box.

"I remembered an article about a Japanese company that had built cleaning robots and thought they should be on the market soon. After waiting a while and not seeing any progress, I decided to build my own."

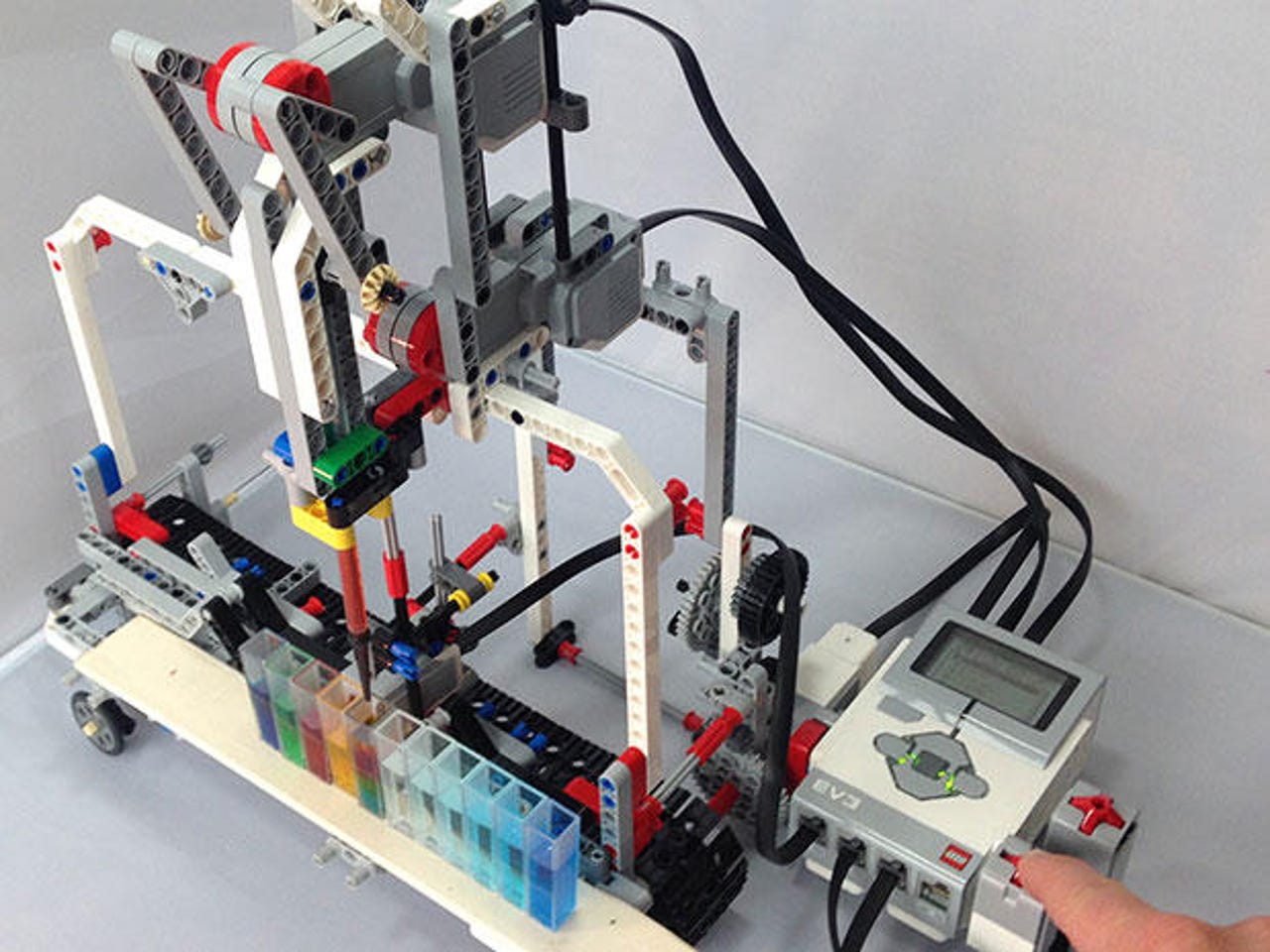

Lucas, who has no engineering background but professes a love for technology and a tinkerer's persistence, built his first autonomous commercial vacuum for less than a thousand dollars. "My wife and sons nickname it Mal, because it "malfunctioned" like the dickens. The name stuck but the robot improved. I then adapted that technology to my auto scrubbers for hard surface floors."

Autonomous floor scrubbers already exist, but they're expensive, starting at around $25,000. Big retailers like Walmart have adopted the technology, but the broader industry has been slow to automate. Lucas thought he could do better.

"I approached this in a simple way. I thought about how I mow my lawn. I pick a spot to start, go around until I am back to where I started, and then switch to the next circuit. I continue this pattern until I am finished."

Lucas wanted to design a robot that used a similar strategy. He began doing research and homed in on sonic sensors, which can sense the walls along a hallway or in a room. The sensors are cheap, about a buck apiece. Next Lucas began looking into microprocessors and conceiving of a software architecture. He found that motors and motor controllers for his application were all readily available.

"Once the robot reaches the starting location," he says, proud to show off the final product, "a sensor triggers the robot to switch to the next cleaning circuit, at which time the robot sends a message via smartphone app to the on-site personnel that the first cleaning circuit is completed. This process continues until all cleaning circuits are completed, at which time the robot is back at the starting point and sends a final message that all cleaning is completed."

Lucas did most of the coding himself, though he hired someone to improve on his work and develop the app. Figuring out what he calls "the how and the why" of the switching system was the most challenging part of the development process. Lucas wanted to design his robot to work in new environments with no hand-holding. Most industrial floor scrubbing robots require a human to guide the machine around the cleaning area the first time out. Robots of this type store a map they can later follow autonomously.

"My robot only requires a starting location at which the starting location marker is placed. The layout does not matter as long as an auto scrubber can clean. Ideally, it works best in long hallways and corridors."

And productivity? It's soared.

"Say the building takes a total of four hours to clean. Dust mopping and wet mopping the hallways takes nearly an hour to complete. Now, with Mal taking over the dust mopping and wet mopping, the building takes three hours of labor or a 25% savings."

That translates into significant savings for his business.

"What I was paying say nearly $60 per night to clean I can now get done for $45 per night. Although, one hour per night does not sound like a lot but start multiplying that times multiple buildings every night and the savings start to add up."

Given the productivity boost, Lucas assumed people would be beating a path to his door. But automation is a tough concept for many legacy businesses to grapple with.

Must read

- 5 things to know about soft robotics (TechRepublic)

- Why learning to code won't save you from losing your job to a robot (TechRepublic)

- Sophia the robot walks for the first time (CNET)

- Amazon may be building an Alexa home robot (CNET)

"I have written and talked to hundreds of people regarding my robots and of great surprise, at least to me, there is very little interest. My hope was to sell the kits in the $3,000 to $4,000-dollar range or as a monthly service at a fraction of the current hourly rate."

For the time being, Lucas is content to use his innovative automation solution to increase productivity in his own business. The robots give him an edge over the competition in a state where the minimum wage tops $15 and there's a persistent shortage of workers.

"Living in Alaska, high wages and labor shortages have always been an issue," he says. "Now, the rest of the nation is experiencing these issues as well as other countries."

Those challenges are spurring innovation, and people like Curtis Lucas are taking the once-rarified world of technology development into their own hands in response.

Humans vs. Robots, which species is winning?

Previous and related coverage:

Robotics in business: Everything humans need to know

An executive guide to the technology and market drivers behind the $135 billion roboticsmarket.

Living Machines: A quick history of robots (Part I)

Derided as abominations or celebrated as ingenious feats of human engineering, robots have been around longer than you think.

Wanted: Robot life coach (no, really)

The unique job is a hint of what's to come as robots increasingly join us in the human world

Gorgeous robots made of high tech paper are mesmerizing

Fifty students were given this shapeshifting paper and told to let their imaginations run wild. Here's what they came up with.