Photos: Come in Willy Wonka, your time is up - meet the printer that prints in chocolate

Printer that makes 3D chocolate objects

Every chocoholic's dream come true, developed by UK researchers...

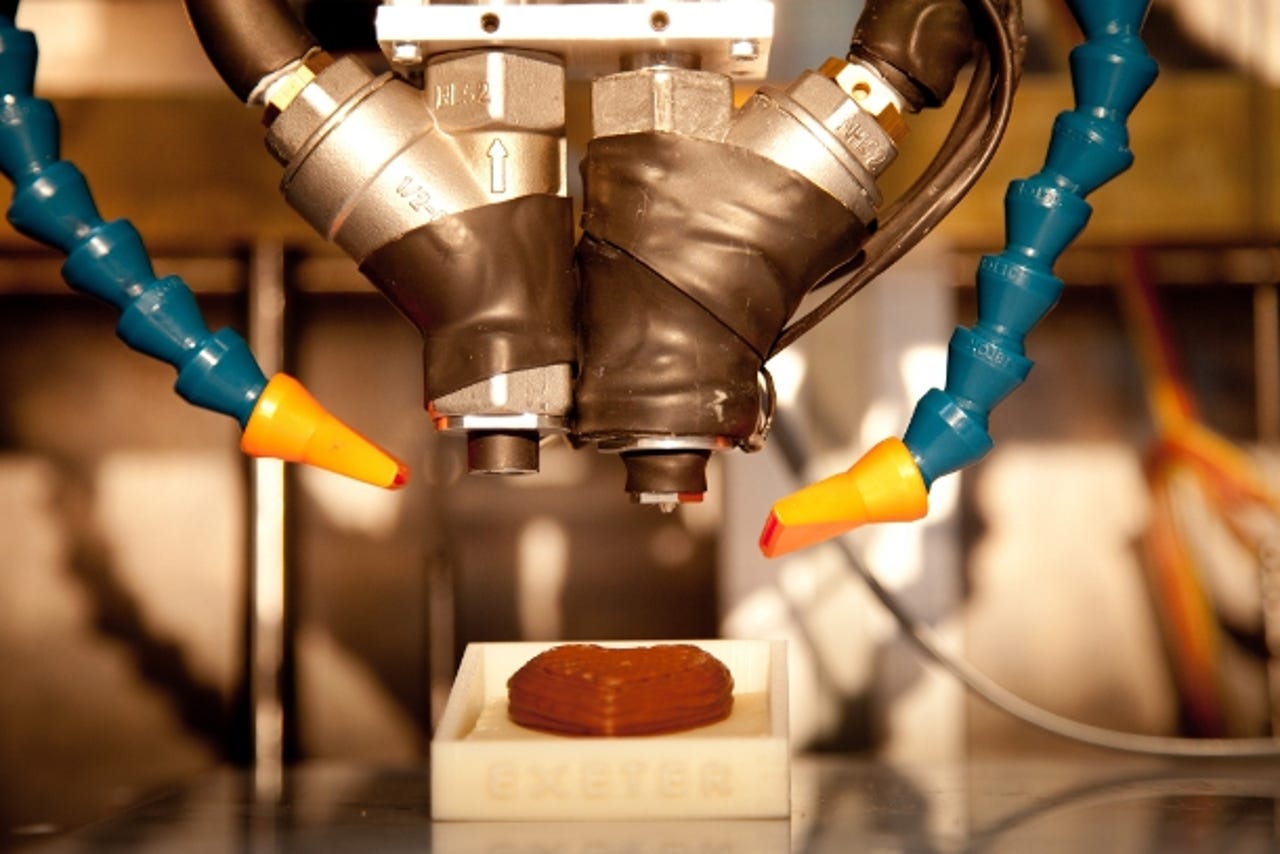

A machine that can print 3D objects in chocolate has been developed by researchers at the University of Exeter.

The 3D printing technology works by building up successive layers of material and is already used for plastic and metal products.

The researchers at the University of Exeter, however, are the first to use the technology to create chocolate objects.

Printer that makes 3D chocolate objects

Dr Liang Hao, who led the project at Exeter, told silicon.com the printer can print any design sent to it, so people can watch the 3D chocolate design of their choice printed in front of them.

"People love chocolate. This will provide huge commercial opportunity," Hao said.

Printer that makes 3D chocolate objects

The research team, pictured above with the 3D printer, initially found chocolate a difficult medium to work with as it requires precise heating and cooling cycles that had to be integrated with flow rates for the 3D printing process.

However, the researchers successfully developed a temperature control system that enables chocolate to be printed by the machine.

Printer that makes 3D chocolate objects

The chocolate printer was developed by the University of Exeter in partnership with the Engineering and Physical Sciences Research Council (EPSRC).

According to Professor Dave Delpy, chief executive of EPSRC, the development of the chocolate printer is "a good example of how creative research can be applied to create new manufacturing and retail ideas.

"By combining developments in engineering with the commercial potential of the digital economy, we can see a glimpse into the future of new markets - creating new jobs and, in this case, sweet business opportunities," Delpy said in a statement.

Dr Liang Hao, University of Exeter

"3D printing technology is a very attractive digital manufacturing process, especially when it is adopted for people's favourite food and gift: chocolate," Exeter's Hao told silicon.com.

The next step will be to develop a "digital design and web community service for people to design their own products and share their ideas and creative experience", Hao said.

The printers could then be linked to the internet, allowing consumers to send their designs directly to the printers.