Autodesk, NASA rethink interplanetary lander design

Featured

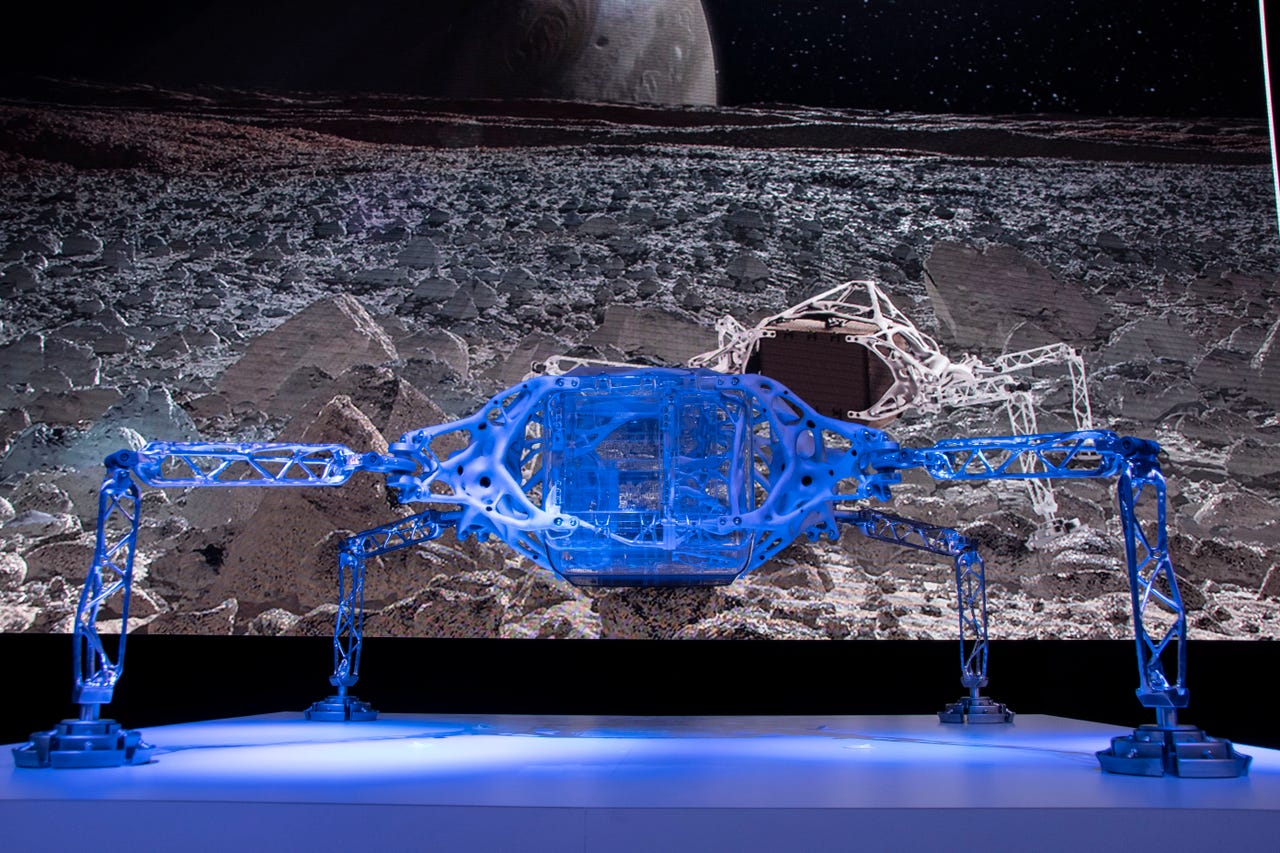

In 2012, the Curiosity rover successfully landed on Mars, thanks in part to the designers and engineers from NASA's Jet Propulsion Laboratory. Now, the NASA JPL has set its sights on a greater challenge: getting a lander all the way to the moons of Saturn and Jupiter. To get closer to that goal, researchers from the JPL teamed up with Autodesk to explore new approaches to designing and manufacturing interplanetary landers. They built a concept lander, which was unveiled Tuesday at Autodesk University in Las Vegas.

ZDNet: Black Friday 2018 deals: Business Bargain Hunter's top picks | Cyber Monday 2018 deals: Business Bargain Hunter's top picks

The lander is the result of a multi-year collaboration and was built using a custom application of Autodesk's generative design technology. The goal was to build a structure that could withstand the harsh conditions of space and travel extremely long distances.

While Mars is 35 million miles away, Jupiter is 365 million miles away, and Saturn is another 381 million miles past that. To travel that distance and accomplish an exploration mission, the lander would have to have enough fuel. Keeping the structure lightweight is key. It would also have to be able to perform complicated operations in extremely cold temperatures and withstand extreme radiation levels.

Generative design helps designers quickly explore all possible design variations for a product. The method gives designers different options for their product designs based on their set of constraints -- such as materials being used, the product's weight or manufacturing methods. Leveraging the cloud and machine learning, it can quickly offer dozens or even hundreds of options.

CNET: Black Friday 2018: The best deals on sale right now | The best Black Friday deals of 2018: The Cheapskate's picks | Black Friday 2018 Amazon deals now available

In April, Autodesk incorporated generative design into its product development tool, Autodesk Fusion 360 Ultimate. For this project, researchers used a more conceptually advanced version of the software that Autodesk developed for experimental capacities.

"We had developed a custom version of our software for high performance motorsports that enabled us to help our customers solve for multiple constraints at once," Mark Davis, the senior director of industry research at Autodesk, explained in a statement. "We then applied it to the problems JPL needed to consider. We took a system that was developed to help our customer solve system level suspension problems on a Formula One race car and applied new requirements for structural constraints critical to space exploration."

TechRepublic: Black Friday 2018: Best deals for professionals | Adobe Creative Cloud gets 25% discount for Black Friday | A guide to tech and non-tech holiday gifts to buy online

Specifically, the JPL team used generative design for multiple structural components, including the internal structure that holds the scientific instruments, as well as the external structure that connects the lander legs to the main payload box. Compared to the baseline design they started with, the team was able to reduce the mass of the external structure by 35 percent.

Best gifts for co-workers under $50 on Amazon

Best Black Friday 2018 deals:

- Amazon Seven Days of Black Friday Deals: All-time lows on office devices

- Amazon Black Friday 2018 deals: See early sales on Echo, Fire HD

- Best Buy Black Friday 2018 deals: Deep discounts on Apple Mac, Microsoft Surface

- Costco Black Friday 2018 deals: $250 iPad, $200 laptops

- Staples Black Friday 2018 deals: PC sales include $150 Chromebook

- Target Black Friday 2018 deals: $250 iPad mini 4, $120 Chromebook

- BJs Black Friday 2018 deals: Laptop, desktop, and tablet sales galore

- Walmart Black Friday 2018 deals: $99 Chromebook, $89 Windows 2-in-1

- Dell Black Friday 2018 deals: $120 Inspiron laptop, $500 gaming desktop

- Jet Black Friday 2018 deals: $195 Roomba, $70 off Nest Cam Indoor

- Newegg Black Friday 2018 deals: $50 off Moto G6, $70 off Nest thermostat

- Office Depot Black Friday 2018 deals: $300 off Lenovo Flex, $129 HP Chromebook

- Sam's Club Black Friday 2018 deals: Buy a 4K TV and get a free Xbox One S

- eBay Black Friday 2018 deals: See early sales on Galaxy Watch, Chromecast

- Lenovo Black Friday 2018 deals: ThinkPad laptops and more

- Microsoft Store Black Friday 2018 deals: Ad showcases Surface, laptop deals

- Google Store Black Friday 2018 deals: Home Hub, Pixel 3, and Pixelbook

- HP Black Friday 2018 deals: Pavilion laptops, desktops

- Windows laptops Black Friday deals: Dell, HP, Lenovo

- Chromebook Black Friday 2018 deals: Dell, Google, HP

- Best tablet Black Friday deals: Apple iPad, Amazon Fire

- Black Friday 2018 iPhone deals: $400 iPhone X gift card, BOGO iPhone XR

- Black Friday 2018 smartphone deals: OnePlus 6T, LG G7